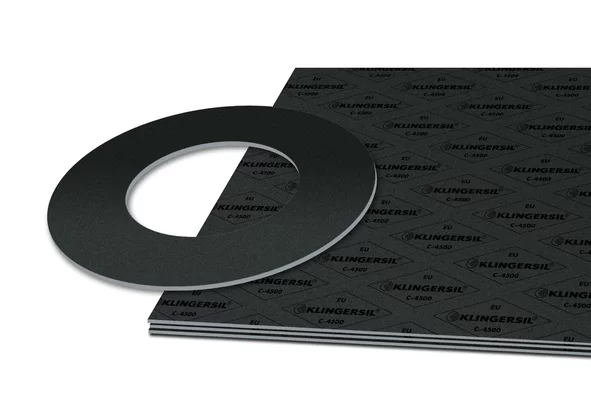

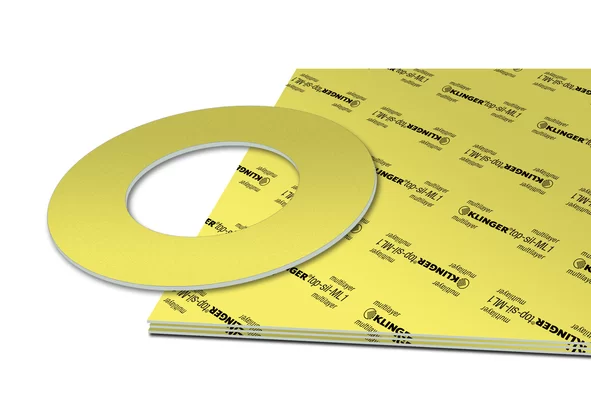

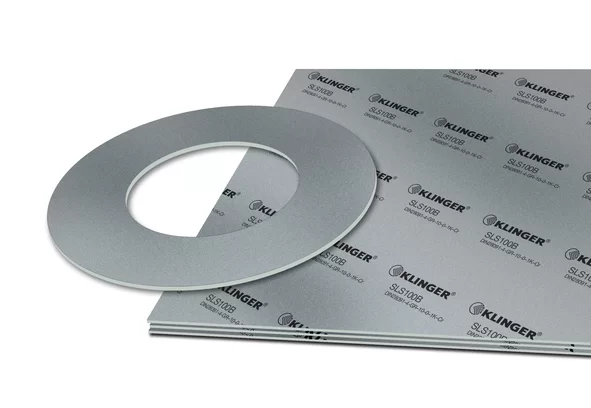

Salmarcon Salgraf SGS 3 sheets provide great chemical resistance, high elasticity and thermal stability. Recommended for aplications involving high sealing stress and where high blowout resistance is required.

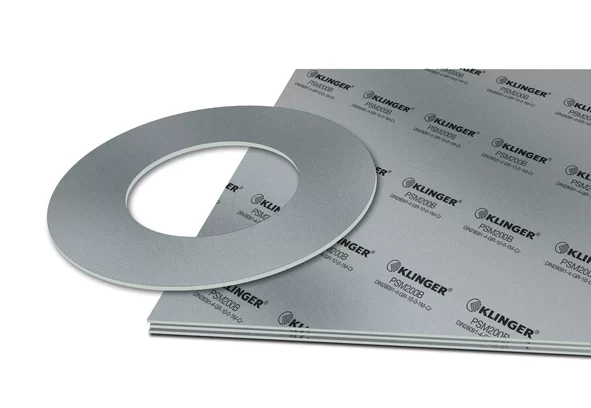

Basis

Graphite laminate reinforced with a 316L tanged stainless steel core.

Areas of application

Power generation, petro-chemical, oil and gas industries, high-temperature and chemical equipment.

Key features

» Great chemical and thermal resistance

» High recovery and compressibility

» Low sulfur content

» Suitable for oxidising and corrosive medias (Salgraf SGS3 )

» Blow-out safety

» Anti-sticking properties in accordance with ASTM F607

Benefits

» Low leakage (conformity to DIN 3535-6)

» Fire-safety approved (API Specification 6FB)

Certificates & Approvals

» TA LUFT (Clean Air)

» FIRE SAFE (API 6 FB)