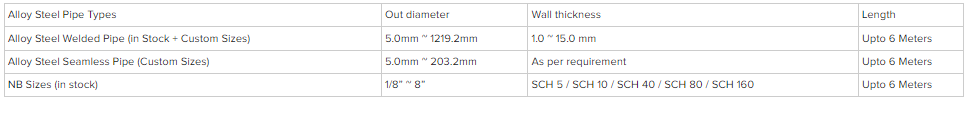

Size:Outside Diameter: OD:6-720MM,WT:0.5-120MM, Length: Single Random, Double Random, Cut Length max to 23m

Standard & Grade:ASTM A691, ASTM A530/A530M, ASTM A335 (ASME SA335), ASTM A387, ASTM A213, etc.

Ends :Plain End, Beveled End, Thread End

Usage:In Petroleum, Aerospace, Chemical, Power, Boilers, Military Industry

Description

Alloy steel welded pipe belongs to the family of the alloy steel pipe. It is named according to the manufacturing technique of a steel pipe. It is manufactured from plate or from continuous coils or strips.

Alloy steel welded pipe is found in an extensive range of applications such as in petroleum, aerospace, chemical equipment, sea water equipment, heat exchangers, power generation, boilers, gas processing, military industry

Specification

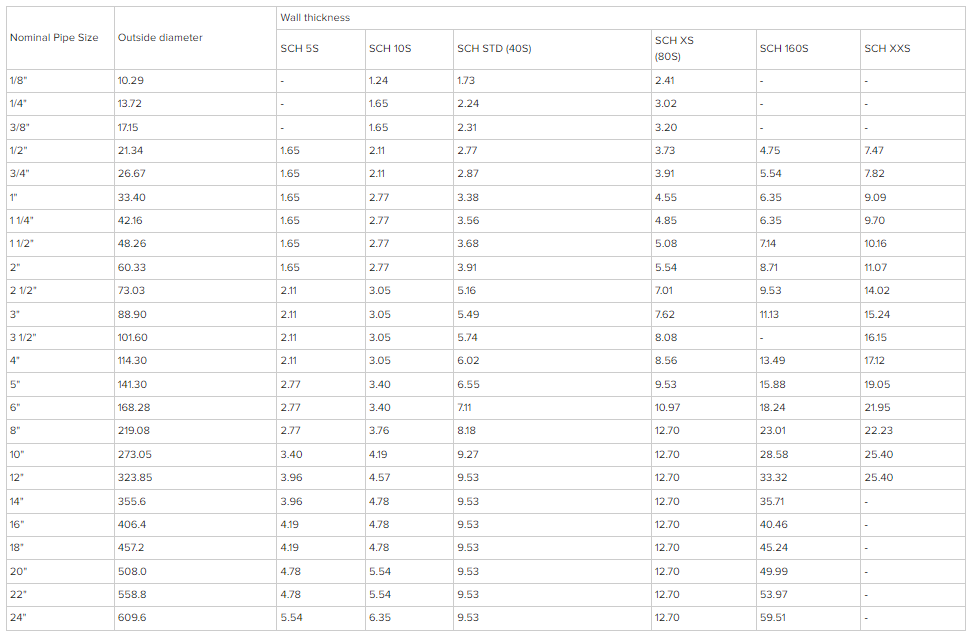

Sizes:1 / 8″ NB – 24″ NB

Thickness:0.3mm – 50 mm, SCH 5, SCH10, SCH 40, SCH 80, SCH 80S, SCH 160, SCH XXS, SCH XS

Type:Seamless / ERW / Welded / Fabricated / CDW

Length:Single Random, Double Random & Required Length

End:Plain End, Beveled End, Threaded

Description

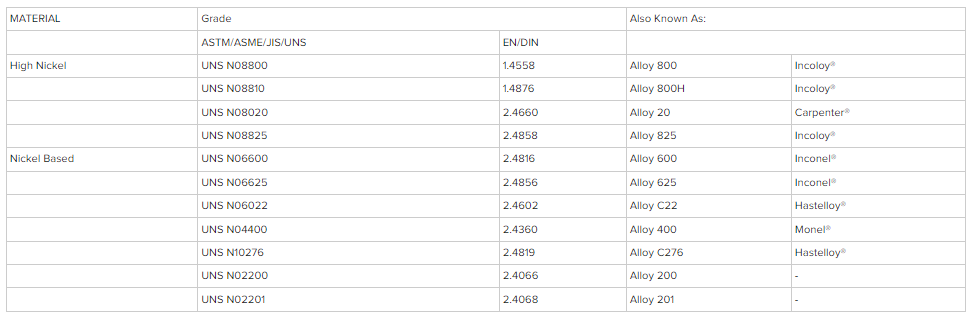

Nickel and nickel alloys are mainly used for corrosion resistance and/or heat resistance including aircraft gas turbines, steam turbine power, plants, medical applications, nuclear power systems, chemical and petrochemical industries. Inconel alloys are oxidation and corrosion resistant materials well suited for service in extreme environments subjected to pressure and heat.

Monel is resistant to corrosion and acids, and some alloys can withstand a fire in pure oxygen. It is commonly used in applications with highly corrosive conditions.

Common alloys for custom pipe & fittings include: Alloy 200, 201, 330, 400, 600, 601, 625, 718, 800, 800H, 800HP, 800HT, 825, 904L, AL6XN, Alloy 20, Alloy K500, C22, C276, Hastelloy X®, Inconel®, Monel®, Incoloy®.

Monel >> Monel 400, Monel K-500, Monel R405

inconel 718 forged bar, Inconel 718 round bar Price ,Astm B637,Astm B637 Forged Round Bar Inconel 718 price

Inconel >> Inconel 600, Inconel 601, Inconel 625, Inconel 617, Inconel 690, Inconel 718,

Inconel X-750, Inconel 926

inconel 718 forged bar, Inconel 718 round bar Price ,Astm B637,Astm B637 Forged Round Bar Inconel 718 price

Incoloy >> Incoloy A-286, Incoloy 800, Incoloy 800H, Incoloy 800HT, Incoloy 825, Incoloy 926, Nimonic 75, Nimonic 80A, Nimonic 263, Nimonic 90, Incoloy 901, Incoloy 925

inconel 718 forged bar, Inconel 718 round bar Price ,Astm B637,Astm B637 Forged Round Bar Inconel 718 price

Hastelloy >> Hastelloy C-276, Hastelloy C-22, Hastelloy C-4, Hastelloy B-2, Hastelloy B-3,

Hastelloy X, Hastelloy G, Hastelloy G2, Hastelloy G3, Hastelloy G30

inconel 718 forged bar, Inconel 718 round bar Price ,Astm B637,Astm B637 Forged Round Bar Inconel 718 price

Austenitic stainless steel >> 904L, Nitronic 60, XM-19, Nitronic 40, 316Ti, 316N, 316LN, 317,317L, 310S, 253MA

inconel 718 forged bar, Inconel 718 round bar Price ,Astm B637,Astm B637 Forged Round Bar Inconel 718 price

DP Steel >> 254SMO, F50, 2205, F53, F55 (ZEROM 100) , F60, F61, F65

inconel 718 forged bar, Inconel 718 round bar Price ,Astm B637,Astm B637 Forged Round Bar Inconel 718 price

PH Steel >> 15-5PH, 17-4PH, 17-7PH

Specification

Sizes:Diameter:16-1016mm

Thickness: 2—120mm

Steel grade: P1 P2 P5 P9 P11 P12 P22

Surface: oiled, black painted to prevent rust

APPLICATION Fileds:Industrial Boilers, Power Plants, Nuclear Plants

Description

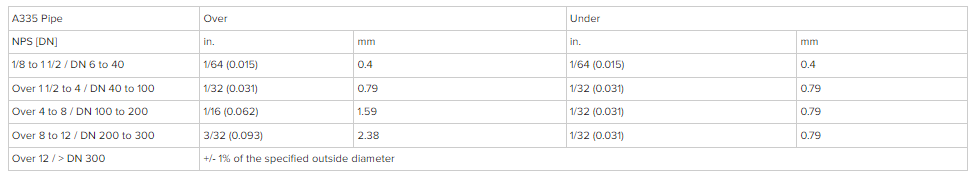

ASTM A335 covers “low-alloy” steel pipes, i.e. pipes that have a total amount of alloying elements below 5%. The addition of higher percentages of alloying elements (example Nickel and Chromium) transforms the steel into higher alloys, like stainless steel, duplex, up to super-alloyed materials like Inconel, Hastelloy, Monel, etc.

Alloy steel pipes are used in the energy industry for high temperature and very low-temperature service (cryogenic), or for applications with very high pressures.

Sizes:Diameter:16-1016mm

Thickness: 2—120mm

Steel grade: P1 P2 P5 P9 P11 P12 P22

Surface: oiled, black painted to prevent rust

APPLICATION Fileds:Industrial Boilers, Power Plants, Nuclear Plants

Karnova can provide ASTM A335 Steel Pipe for factory price, passed ISO9001, SGS and other certificates, accept third-party testing, has complete testing and testing facilities, from product development, raw material supply, production process management, etc. in accordance with international quality The system standards are standardized to provide customers with satisfactory pre-sale, in-sale and after-sale services. Feel free to contact us anytime

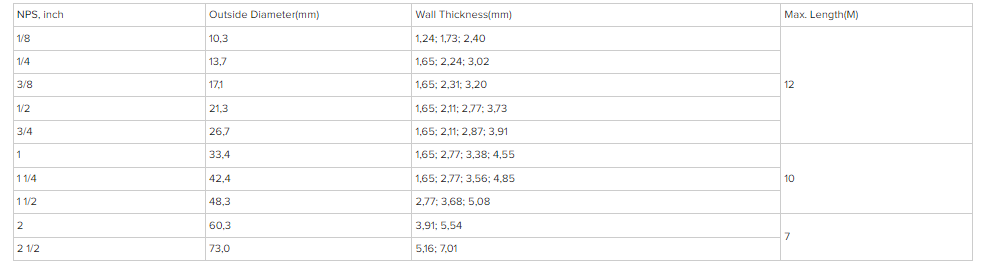

Specification

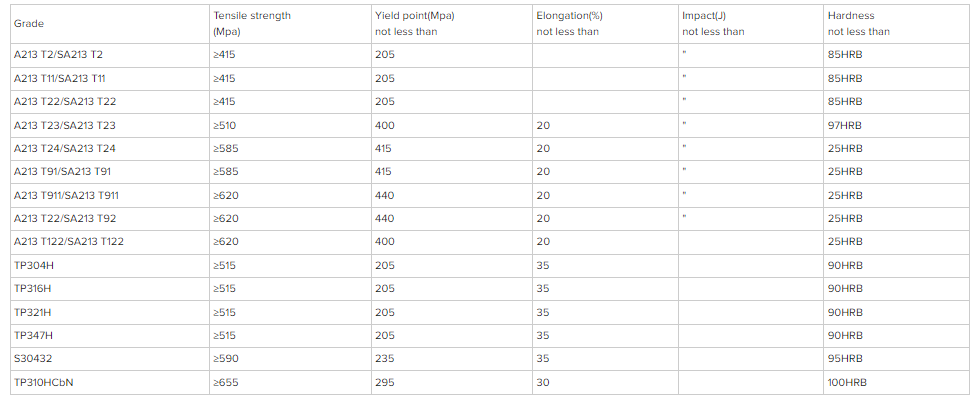

Main grades: ASTM A213 T5, T5b, T9, T11, T91 and T22

Size range:

NPS 1/4” to NPS 24”

Wall Thickness – Schedules 40 through 160, STD, XS, XXS.

Unscheduled heavy wall pipe thicknesses available up to 4 inches

Description

Centerway steel co.,ltd is the leading ASTM A213 alloy steel tube manufacturers and suppliers, if you want to buy or import A213/SA213 T2, A213/SA213 T5, A213/SA213 T9, A213/SA213 T11, A213/SA213 T12, A213/SA213 T22, A213/SA213 T91, A213/SA213 T92 alloy steel tube,

ASTM A213 Alloy Tubes are been widely used in high temperature services especially for the boiler and superheater.

Specification

Standard

Mechanical Properties

Size range(mm):Out diameter:10-324mm;Wall Thickness:1-30mm;Length:14000mm max

Grade:ASTM A519 1020;1025;1026;1035;1045;4130;4140

Application:

For mechanical engineering

For mechanical and pressure use,and also for transporting steam,water,gas and etc

Description

This specification covers for several grades of carbon and alloy steel mechanical tubing, either hot-finished or cold-finished. The steel used in the mechanical tubing may be cast in ingots or may be strand cast. When steel of different grades is sequentially strand cast, identification of the resultant transition material is required. The seamless tubing is a tubular product made without a welded seam. It is usually manufactured by hot working steel, and if necessary, by subsequently cold finishing the hot-worked tubular product to produce the desired shape, dimensions and properties. The tubes shall be furnished in the following shapes: round, square, rectangular and special sections. Heat analysis shall be made to determine the percentages of the elements specified. If secondary melting processes are used, the heat analysis shall be obtained from one remelted ingot or the product of one remelted ingot of each primary melt. The tubing shall be coated with a film of oil before shaping to retard rust when specified.

Specification

This ASTM A519 specification covers for several grades of carbon and alloy steel mechanical tubing, either