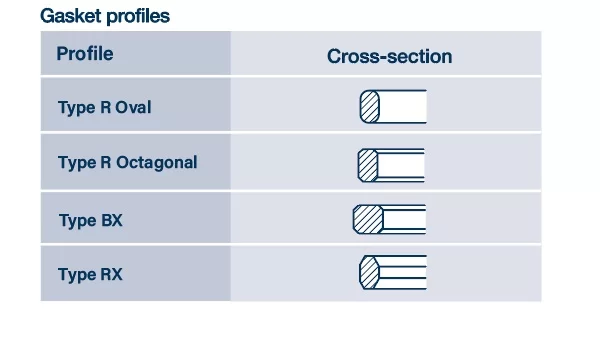

Ring Type Joints [RTJ] are heavy-duty, high-pressure gaskets largely used in offshore petrochemical applications and can be manufactured from a number of materials to suit the process media and the flange materials.

RTJ are precision machined metallic rings which are designed to be used with API 6B, ASME B16.5 and API 6BX [dependent on the gasket style] flanges. As indicated, RTJs are often used in offshore applications and certain styles can be adapted for subsea installation.

We hold a large range of RTJs in stock in a number of profiles and materials.

Basis

Metal, Carbon, Monel, Inconel, Titanium and various coating or as per request.

Areas of application

›› Oil processing

›› Petrochemical industry

›› Powerplants

›› Grooved flanges

General properties

» Economical

» Easy to handle and install

» Suitable for high temperatures

» Good blow-out resistance

Benefits

» Withstands up to 1000°C

» Bares pressure up to 1300 bar

» Superior chemical resistance

» No ageing of the material

Welding Ring (Gapolet) is a split ring that is engineered and designed to give you a pre measured 1/16″ minimum gap for socket welds.

Basis

Certified stainless steel.

Areas of application

» Power piping nuclear

» Conventional, Industrial piping

» Petrochemical and Fertilizer plants

» Ship building etc..

Key features

» Resists corrosion from chemicals, radioactive materials, and water.

» The spring tension makes it fit tightly into all standard sized fittings from 1/4″ to 2″. (Non-standard sizes are available upon request).

» Consistent material composition

Benefits

» Once inserted into the fitting the ring becomes a permanent part of the joint.

» It will not rattle or vibrate even under extreme pressure.

» Superior chemical resistance

» No ageing of the material

The IX seal ring design exists in one size per DN covering all pressure classes in this product standard and the ring gaskets usually be coated with PTFE.

The NORSOK IX seal ring gaskets are designed and used where the NORSOK CFC (Compact Flange Connections) are in use. The IX seal ring is designated as described in the Key features. The designation elements shall be separated by / (slash). The number of characters is not fixed.

Basis

Low Carbon Steel, Duplex, and Inconel 625 with various type of materials as per requests.

Areas of application

NORSOK IX seal ring gaskets are mainly used for high pressure and high temperature applications when applying as per NORSOK L-005 Compact Flanged Connections .

Key features

» Standard identification – NCF5

» Type – and ring size – IX and the appropriate DN

» Material designation

Benefits

» High integrity seal at high pressures

» PTFE coating improves corrosion resistance and provides easy identification

» Good chemical resistance

» Designed to create a high integrity joint with primary and secondary seals

The lens ring type Joint gasket is usually a line contact seal for use in high pressure piping devices as well as in pressure vessel heads. This lens cross section is often a spherical gasket surface area and requires specific machining on the flanges. In obtaining lens gaskets, complete drawings and product technical specs need to be supplied.

Basis

Soft iron, SS 304, SS 316L, SS 321, SS 347, 5Cr-0.5Mo, Inconel 600, Incoloy 825, Monel 400, Nickel 200, Hastelloy B2, Hastelloy C276 Lens Ring Type Joint Gasket.

Areas of application

» Oil and gas

» Petrochemical and offshore industries vessel heads

» Valves and pipe works assemblies

Key features

» With our lines of advanced machine, quality tesing machine and skilled technical workers we can make all kinds of LRT joint gaskets

» For the use with high pressure piping devices

» For the use with high pressure vessel heads

Benefits

» Resists high surface pressures also at elevated temperatures

» Superior chemical resistance

» No ageing of the material

Metal diaphragm seal for the welding is a type of gasket used for flat covers in exchangers operating works at high temperatures, high pressures or with a high level of both of these two parameters in same time.

They are also used for the hazardous conditions like as in hydrogen installations.

Basis

They are made of a thin plates of special alloys (Alloy 20, Hastelloy, Monel, Inconel, titanium) , stainless steels (several grades) or several other metals are in common use where high pressure and high temperature ratings and specific chemical compatibility are required.

Areas of application

General Industry, Petrochemical (Oil & Gas), Shell & Tube Heat Exchangers especially for high temperature and high temperatures.

Key features

» Suitably to used for the hazardous conditions

» Excellent high temperature and pressure property

» Certain elasticity; it is reducing the stress generated by either welding or by exposure to pressure and temperature.

Benefits

» Their sphericity is closely matched to the motion conditions and ensures consistent moves of its peripheral part as well as that of the internal part of the shell

» Provide ‘side’ access to ‘main weld’ during installation and dismantling, facilitate reusing of diaphragm (especially important when often open – close operations necessary)

» Reduce cost and expenses of the re-install as no flange refurbishment is necessary (after the main weld cut off).

The piping system is the lifeline of industrial processes. Generally, it includes the complete interconnection of pipes and components like pipe fittings, flanges, tanks, pressure hoses, joints, traps, pumps, gaskets, and valves.

Piping and Special piping materials that we produce hinder the effects of heat, corrosion and high temperature.

Basis

Super Duplex (UNS S32750) , Duplex (UNS S31803), Nickel Alloy and Titanium Gr.2, Gr.7, Gr.10, Gr.12 as well as Monel, Inconel, Duplex, Super Duplex and more.

Karnora alloy flanges show excellent corrosion and oxidation resistance. We supply also Special Alloy Flanges as tailor made solutions for your project requirements.

Basis

Super Duplex, Duplex, Nickel Alloy and, Titanium Gr.2, Gr.7, Gr.10, Gr.12 as well as S32750, S31813, Monel, İnconnel, Duplex, Super Duplex and more.

Areas of application

» Food production

» Oil and gas industry

» Water supply

» Chemical plants and many more

Key features

» Mechanically stable

» Resistant to creep and cold flow

» Consistent material composition

Benefits

» Resists high surface pressures also at elevated temperatures

» High retention of the bolt load

» Superior chemical resistance

» No ageing of the material