Size Range: 1/2” – 120” ( DN 15 – DN 3000)

Rating: 150, 300, 400, 600, 900, 1500, 2500;

Type: Welding Neck, Long Welding neck, Slip on, Blind, Spectacle Blind,

Lap joint, Socket weld, Threaded, Orifice, Ring Joint Flange,

Spacer and Blank, Anchor Flange, API flange, etc.

Standard: ANSI B16.5, ANSI B16.47 Series A & Series B, AWWA C207, BS4504,

BS3293, DIN EN1092-1, API590, JIS/KS, ISO 7005-1, JB/T, etc.

Material: Carbon steel, Low Temperature Carbon Steel, High Yield Carbon Steel,

Plate Material, Low Alloy Steel, Stainless Steel, Duplex Stainless Steel.

C.S: A36, A105, A266 CL2/CL4, ST37.2, C22.8, S235JR, S355JR;

LTCS: A350 LF2 CL1/CL2/LF3;

HYCS: A694 F42/F52/F60/F62/F65/F70;

Plate: A515 Gr60/70, A516 Gr 60/70, A285 Gr A B C, A240 304, A240 316

LAS: A182 F5, F9, F11 CL1/CL2/CL3, F12 CL1/CL2, F22 CL1/CL3, F91

SS: A182 F304/L, F304H, F316/L, F317/L, F44

Duplex SS: A182 F51/UNS 31803, F53/UNS 32750

Application: Can be widely used in the field of Gas, Oil, Pipeline,Water Supply, Electricity and Machinery.

Type: Seamless / Welded

Size Range: 1/2” – 24” ( DN 21.3 – DN 610) for Seamless;

26” – 96” ( DN 660 – DN 2438.4) for Welded.

Wall Thickness: SCH 5S – XXS

Style: Long Radius (LR) / Short Radius (SR)

Angle: 45 Degree, 90 Degree, 180 Degree or in specified degree.

Standard: ASME/ANSI B16.9, ASME B16.28, MSS SP43, DIN2605,

DIN2617, DIN2516, JISB2311, etc.

Material: Carbon steel, Low Temperature Carbon Steel,

High Yield Carbon Steel, Alloy Steel, Stainless Steel.

C.S: ASTM/ASME A234 WPB / WPC, ST37.0, ST35.8, ST45.8;

LTCS: A420 WPL6, ASTM/ASME A402 WPL3 / WPL6;

HYCS: ASTM/ASME A860 WPHY 42 / 46 / 52 / 60 / 65 / 70;

AS: ASTM/ASME A234 WP1 / WP12 / WP11 / WP22 / WP5 / WP9

/ WP91 / 15Mo3 / 15CrMoV / 35CrMoV;

SS: ASTM/ASME A403 WP304 / 304L / 304H / 304LN / 304N /

316L / 316H 321H / 347H;

Application: Can be widely used in the field of Chemical,

Construction, Water Supply, Drainage, Oil,

Light & Heavy Industries, Freezing, Sanitation,

Fire Control, Electric Power, Aerospace, shipbuilding, etc.

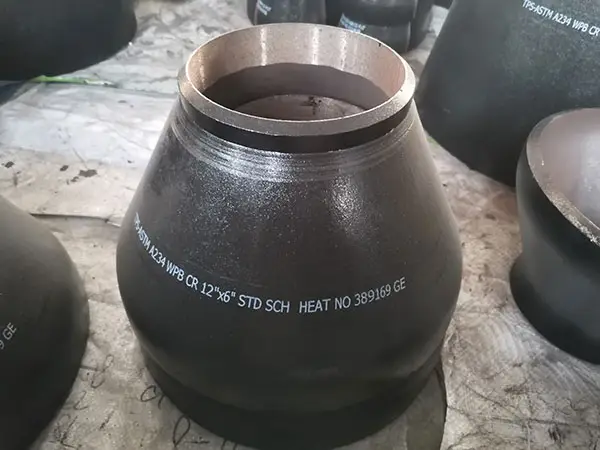

Type: Seamless / Welded

Size Range: 1/2” – 24” ( DN 21.3 – DN 610) for Seamless;

26” – 72” ( DN 660 – DN 1828.8) for Welded.

Wall Thickness: SCH 20 – XXS

Style: Equal / Reducing

Process: Cold-Extruded / Hot-Pressed.

Standard: ASME/ANSI B16.9, GB/T12459, GB/T13401, DIN 2615, SH3408,

SH3409-96, SH3410-96, HG/T21635, DL/T 695, SY/T 0510, etc.

Material: Carbon steel, Low Temperature Carbon Steel,

High Yield Carbon Steel, Alloy Steel, Stainless Steel.

C.S: ASTM/ASME A234 WPB / WPC, ST37.0, ST35.8, ST45.8;

LTCS: A420 WPL6, ASTM/ASME A402 WPL3 / WPL6;

HYCS: ASTM/ASME A860 WPHY 42 / 46 / 52 / 60 / 65 / 70;

AS: ASTM/ASME A234 WP1 / WP12 / WP11 / WP22 / WP5 / WP9 / WP91

/ 15Mo3 / 15CrMoV / 35CrMoV;

SS: ASTM/ASME A403 WP304 / 304L / 304H / 304LN / 304N

/ 316L / 316H 321H / 347H;

Application: Can be widely used in the field of Petroleum,

Aerospace Pharmaceuticals, Chemical, Metallurgy,

Military Industry, Electric Power, Engineering Support, etc.

Standard: ASME B16.9, DIN2615, JIS B2312, ASME B16.11

Material: Carbon Steel ASTM A234 WPB,

Alloy Steel ASTM A234 WP1, WP5, WP9, WP11, WP22

Stainless Steel ASTM A403 304/316

Types: Equal and Reducing

Size Range: 1/2″ to 24″

Wall thickness: Sch10, Sch40, Sch80

Pressure Rations: 3000#, 6000#, 9000#

Concentric Pipe Reducer and Eccentric Pipe Reducer Dimensions are covered in ASME B16.9. Refer to the table given below for the size 1/2″ to 24″.