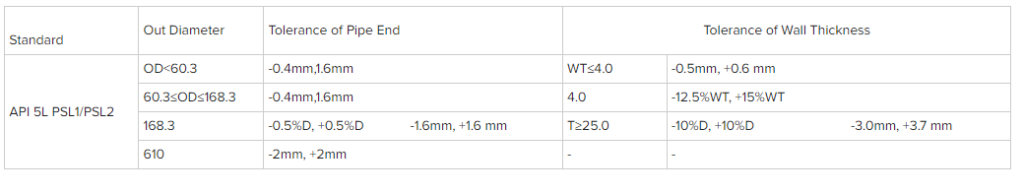

Product Dimension:SMLS:Φ10.3-720 × 1.7-52mm;WELD:Φ219-2134 × 5-52mm

Standard:API SPEC 5L, ISO 3183, EN10208

Uses:For conveying gas,water and oil either in the oil or natural gas industries

Grades: API 5L Grade B, X42, X52, X56, X60, X65, X70, X80

Product Specification Level: PSL1, PSL2, onshore and offshore sour services

Thickness Schedule: SCH 10. SCH 20, SCH 40, SCH STD, SCH 80, SCH XS, to SCH 160

Manufacturing Types: Seamless (Hot Rolled and Cold Rolled), Welded ERW (Electric resistance welded), SAW (Submerged Arc Welded) in LSAW, DSAW, SSAW, HSAW

Ends Type: Beveled ends, Plain ends

Length Range: SRL (Single Random Length), DRL (Double Random Length), 20 FT (6 meter), 40FT (12 meter)or customized

Surface Treatment: Natural, Varnished, Black painting, FBE, 3PE (3LPE), 3PP, CWC (Concrete Weight Coated) CRA Clad or Lined

Description

API 5L pipe is carbon steel pipe used for oil and gas transmissions, it includes the pipes manufactured in seamless and welded (ERW, SAW). Materials covers API 5L Grade B, X42, X46, X52, X56, X60, X65, X70, X80 PSL1 & PSL2 onshore, offshore and sour services. API 5L the implementation standard of steel pipe for pipeline transportation system and specification for line pipe

Specification

Standard and grades: ASTM A53 Grade A, B. Type E, F, S

Manufacturing types: Seamless, ERW, SAW

Pipe Dimensions Range: NPS 1/8” to 26”

Pipe Schedule Range: SCH 10, SCH 40, SCH STD, SCH 80, SCH XS to SCH 160 and SCH XXS

Ends Treatment: Plain, Beveled, threaded. With couplings.

Length range: Single Random Length (SGL), Double random Length (DRL )Fixed length 20 ft (6 m) and 40 ft (12 m)

Surface Coating: Epoxy coatings in 3PE or FBE, Black paint, varnished, anti-rust oil, galvanized

Description

ASTM A53 is a carbon steel alloy, which can be used as structural steel or for low-pressure pipelines.

ASTM A53 seamless and welded steel pipe is a general, all-purpose pipe. Designed for coiling, bending and flanging, A53 carbon steel pipe is suitable for welding. The grades denote certain chemical and mechanical properties and should be noted in selection. A53 pipe is intended for mechanical and pressure applications and is also acceptable for ordinary uses in steam, water, gas and air lines, Low pressure systems, Structural applications, Mechanical components, Bollards, Casing, generator plants, refineries, compressor stations, natural gas transmission, and steam conduction.

A53 pipe comes in three types (F, E, S) and two grades (A, B).

A53 Type F is manufactured with a furnace butt weld or may have a continuous weld (Grade A only)

A53 Type E has an electric resistance weld (Grades A and B)

A53 Type S is a seamless pipe and found in Grades A and B)

Applications

1. Construction: the pipeline underneath, the groundwater, and the hot water transportation.

2. Mechanical processing, bearing sleeves, processing machinery parts, etc.

3. Electrical: Gas delivery, Hydroelectric power fluid pipeline

4. Anti-static tubes for wind power plants, etc.

Specification

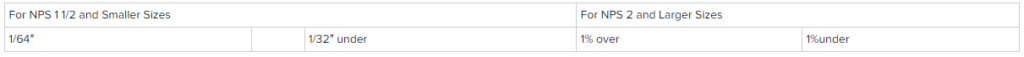

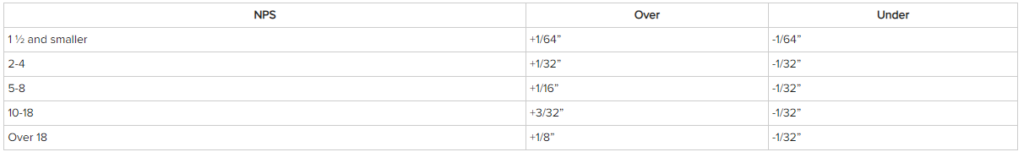

Outside Diameter at any point shall not vary from standard specified more than:

Standard: ASTM A106, Nace, Sour service.

Grade: A, B, C

Range of OD outer diameter: NPS 1/8 inch to NPS 20 inch, 10.13mm to 1219mm

Range of WT wall thickness: SCH 10, SCH 20, SCH STD, SCH 40, SCH 80, to SCH160, SCHXX; 1.24mm up to 1 inch, 25.4mm

Range of length: 20ft to 40ft, 5.8m to 13m, single random lengths of 16 to 22ft, 4.8 to 6.7m, double random length with average 35ft 10.7m

Ends procession: Plain end, beveled, threaded

Coating: Black paint, varnished, epoxy coating, polyethylene coating, FBE and 3PE, CRA Clad and Lined.

Description

ASTM A106 seamless steel pipe covers seamless carbon steel nominal wall pipe for high-temperature service, suitable for bending, flanging and similar forming operations. NPS 1-1/2 and under may be either hot finished or cold drawn. NPS 2 and larger shall be hot finished unless otherwise specified. Surface finish standards are outlined in the specification.

A106 pipe is always produced by the seamless method and can be bent, coiled and flanged and is intended for use in high temperature applications, Pressure systems, Mechanical components, Structural applications, Spreader bars.

Specification

Permissible Variations in Dimension

Wall thickness: The minimum wall thickness at any point shall not be more than 12.5% under the nominal wall thickness specified.

Weights per foot: The weight of any individual length shall not vary more than 10% over and 3.5% under that specified. NOTE – NPS 4 and smaller are weighed in lots. Larger sizes are weighted by individual length.

Outside diameter: Shall not vary from standard specified below at any point.

Lengths of A106 seamless carbon steel pipe

Single random – 16’ – 22’ (5% may be 12’ – 16’)

Double random – Minimum length is 22’. Minimum average is 35’ (5% may be between 16’ – 22’)

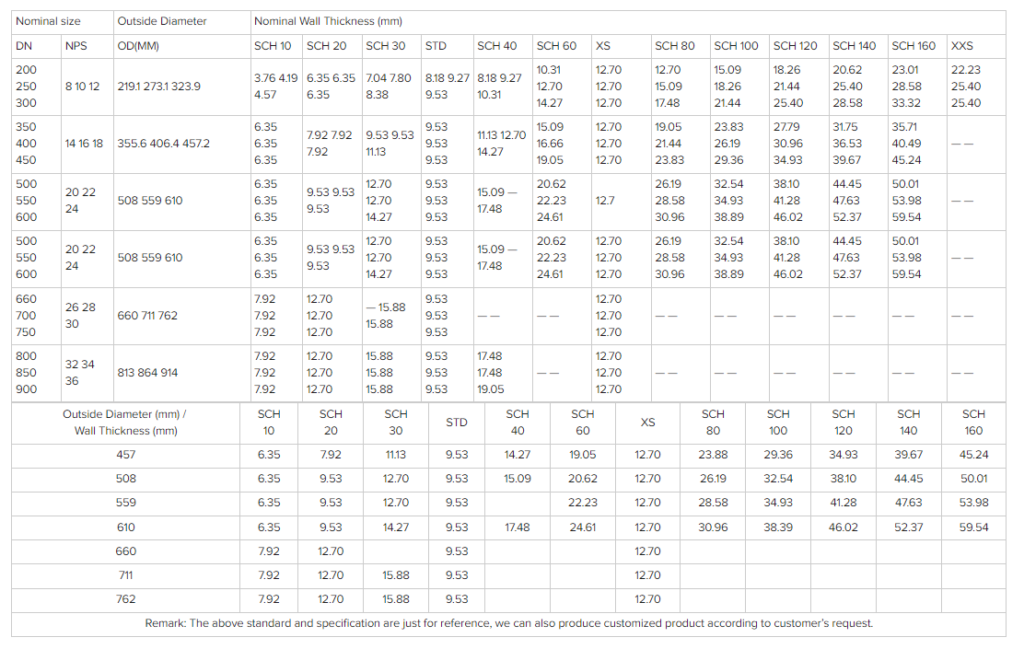

Sizes:1/4″ (8mm)-80″ (2000mm);Thickness: 2.11mm-60mm

SCH: SCH10,SCH20,STD,SCH40,SCH60,XS,SCH80,SCH100,SCH120,SCH160,XXS

Coating:3PE Coating,3PP Coating,FBE Coating,Epoxy Coating,Special Painting

Length:3m-12m

Standards:API 5L, API 5CT, ASTM A53, ASTM A106, ASTM A179, ASTM A192, ASTM A252, ASTM A333, ASTM A335, ASTM A672

Description

Seamless steel pipes are derived from solid steel that is in sheet or bar form and is formed into a solid round shape known as “billets” which are then heated and cast over a form such as a piercing rod to create a hollow tube or shell.The abbreviation of seamless steel pipe is smls pipe

Standard: GB/T8162-1999, ASTM A53, ASTM A106, ASTM A500-98, ASTM A501-98, ASTM A519-98, JIS G3441-1994, JIS G3444-1994, BS EN 10210-1

Application: Used in the general structure and the mechanism, including construction, machinery, transportation, aviation, petroleum mining and each kind of structural tubes

Size: OD: 114mm-914mm;WT: 4mm-60mm;LENGTH: 5.8/6/11.8/12m

Description

Seamless Pipe For Structure (GB/T8162-2008) Is Used For The General Structure And Mechanical Structure Of The Seamless Pipe.Seamless Steel Tube Is Divided Into A Variety Of Different Uses.

Stainless Steel Seamless Pipe For Structure (GB/T14975-2002) Is A Hot-Rolled (Extruded, Expanded) And Cold-Drawn (Rolled) Seamless Pipe Made Of Stainless Steel Used In Chemical, Petroleum, Textile, Medical, Food, Machinery And Other Industries, Corrosion-Resistant Pipes And Structural Parts And Components.

GB/T8162-2008 (Seamless Pipe For Structure) Is Mainly Used For General Structure And Mechanical Structure.Its Representative Material (Brand) : Carbon Steel 20, 45 Steel, Q235, Alloy Steel Q345, 20Cr, 40Cr, 20CrMo, 30-35CrMo, 42CrMo And So On.

Seamless Steel Pipe

Because Of Its Manufacturing Process Is Different, It Is Divided Into Hot Rolled (Extruded) Seamless Steel Tube And Cold Drawn (Rolled) Seamless Steel Tube Two Kinds.Cold-Drawn (Rolled) Pipe Is Divided Into Circular Pipe And Special-Shaped Pipe Two Kinds.

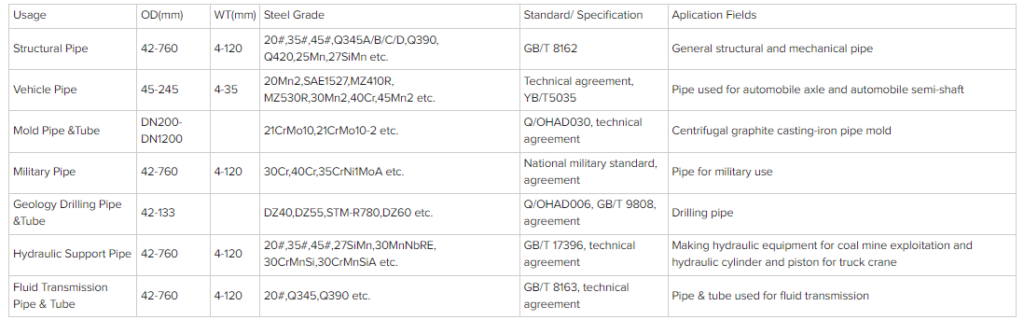

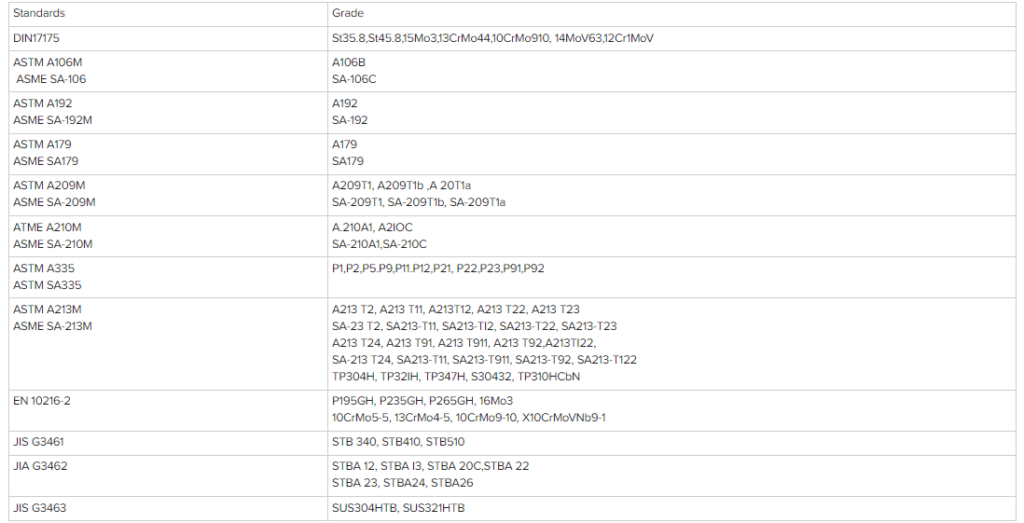

Specification

Note: Steel pipe can be developed and produced to meet the users’ personalized requirements according to their demands.

Product Dimension:

Cold Finaished Seamless Tube and Pipe:Φ8-114.3×1~20mm

Hot-rolled Steel Tube and Pipe:Φ114.3~720×5-120mm

Uses:For manufacture wall panel. econcomizer, reheater superheater and steam pipeline of boiler

Description

A boiler is a closed device that heats fluid (usually water) in. Don’t actually steam the gas. The heated or vaporized fluid leaves the boiler relying on Boiler tubes, cooking, and sanitation for use in different processes or heating applications such as water heating, central heating, power generation.

Standard

Product Dimension:Out Diameter: 21.3-1200mm, Wall Thickness: 2.11-50mm

Standard:ASTM A53M, ASTM A106M, JIS G 3454, JIS G 3455, JIS G 3456

Uses:Fluid pipes are hollow cross section, no welded joint from start to finish. Steel tube with a hollow cross-section, for a large number of pipe conveying fluid pipeline to transport oil, natural gas, coal gas, water and some solid materials.

Description

Fluid pipes are pipes specially used for conveying media with fluid properties.

Medium with fluid properties, in addition to liquid media such as water, oil, and solution, solid media such as cement, grain, and coal powder can also flow under certain conditions.

The fluid tube can be made of steel, copper, titanium and other non-ferrous metals, or even plastic and other non-metallic materials.

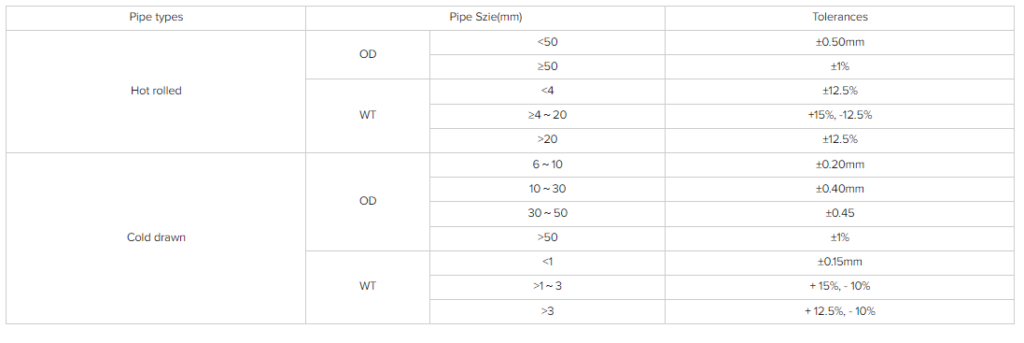

Specification

Dimension Tolerances

Size:Out diameter: 19.05-114.3mm.Wall thickness: 2-14mm.Length: 3m-10m.

Standard & Grade:ASTM A53, ASTM A106, API5L, DIN1629, DIN 17175, BS, JIS, GB.Grade: GR.B, ST35, ST37, ST42, ST35.8-ST45.8, X42, X52, X60.

Surface:black oil coating, galvanized coating, PE

Packing:Bundle or bulk , seaworthy packing or for the client’s requirement

Usage:For conveying gas, water and oil either in the oil or natural gas industries

Description

The hot expanded seamless steel pipe is relatively low density, but the contraction of the strong, seamless steel pipe can be referred to as thermal expansion. The roughing finishing process for expanding the diameter of a pipe by a cross-rolling method or a drawing method. Steel pipe thickening in a short period can produce non-standard and special types of seamless tubes with low-cost and high production efficiency, the current international developments in the field of tube rolling.

Application of hot expanded seamless pipe

- Petrochemical Industries

- Paper industries

- Sugar Factory

- Cement Factory

- Power Plant

- Petroleum Industries

- Chemical Industries

- Shipbuilding Plant

- Construction Industries

- Steel Plant

- Oil Mills Industries

- Fertilizers Industries

- Oil&Gas Industries

- Refineries Industries

- Defense Industries

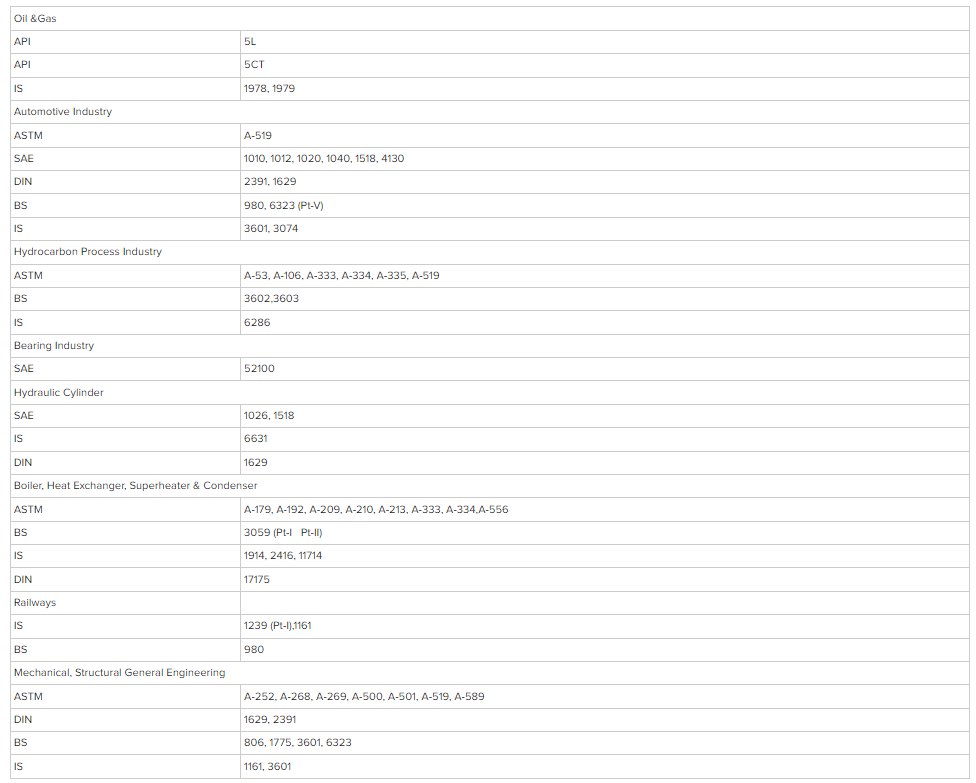

Specification

Grades:

Carbon steel grades: SAE 1020, 1026, 1035; A 106 grade A, B, C; E 355, ST 52, ST 37.4, and so on.

Stainless steel grades: 304 / 304L, 316 / 316L, 316 Ti, 321/321H; 1.4301 /1.4307, 1.4401/1.4404, 1.4541, 1.4571;

Standards:ASTM A519, EN 10305-1, EN 10216-2, EN 10216-5, DIN 2391, DIN 1630, etc.

Size Range:OD:10 – 101 mm;Thickness: 1-10 mm Length:Up to 14 mtr

Description

Cold Drawn Seamless Mechanical Tubing (CDS) is a cold drawn 1018/1026 steel tube which offers uniform tolerances, enhanced machinability and increased strength and tolerances compared to hot-rolled products.

Usage:

1. Pipeline, transportation of fluid or gas;

2. Mechanical parts in automobiles and heavy equipment;

3. Hydraulic equipment, such as hydraulic cylinders;

4. Heat exchanger and boiler tubing;

5. Structural components or agricultural components

Standard

Product Dimension:Out Diameter: 10.3-914.4mm,Wall Thickness: 1.73-200mm, Length:Random Length, Fixed Length, SRL, DRL,1m-12m

Uses:

- Mechanical Tubing

- Using For machining

- Tube for Structures

- For manufacture of pipelines, vessels, equipment, pipe fitings and steel structures

Description

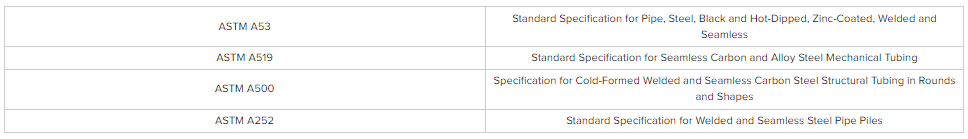

Standard

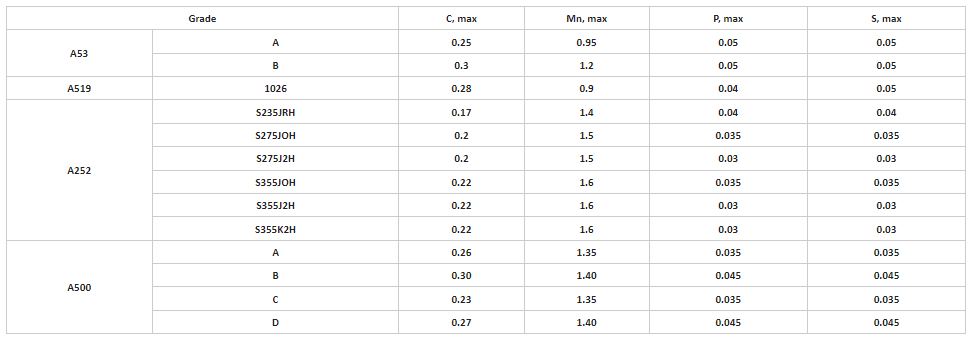

Standards & Grades

ASTM A53/ASME SA53 Grades A & B;

ASTM A519/ASME SA519 Grades 1020,1026,4140,4142;

ASTM A252/ASME SA252,S235JRH, S275JOH, S275J2H, S355JOH, S355J2H, S355K2H;

ASTM A500/ASME SA500 Grades A, B, C, D;

EN10297-1 Grades E235, E275, E315, E355;

EN10210-1 Grades S235JRH, S275JOH, S275J2H, S355JOH, S355J2H, S355K2H;

Note: Other grades of steel pipe can be made avaiable through comsultatioas.

Chemical Composition