Spiral wound gaskets can recover under the action of fluctuating loads caused by process fluid pressure and temperature changes, flange face temperature variations, flange rotation, bolt stress relaxation and creep.

The gasket sealing element consists of a pre-formed metallic winding strip with layers of a softer, more compressible sealing material which, during compression, is densified and flows to fill imperfections in the flange surfaces when the gasket is seated.

The metal strip holds the filler giving the gasket mechanical resistance and resilience. Salmarcon spiral wound gaskets can be manufactured from a range of filler materials according to different service conditions.

Basis

Inner and outer metal core. PTFE, Mica and Graphite fillers.

Areas of application

» Refineries

» Chemical plants

» Gas installations

» Water treatment

» General pipeline construction

Key features

» Can be produced in all sizes from DN 10 or 1/2” to a diameter of 4 metres

» Can be produced in oval-shaped spiral-wound gaskets for the valve and apparatus construction industries

» Oval-shaped inner and/or outer rings are also possible.

Benefits

» Can withstand extreme operational conditions

» No need to support the spiral with an inner ring at smaller nominal diameters

» Lower seating stress required with higher leak-tightness

Certificates & Approvals

• TA-Luft (Clean air)

• Fire Safe (API 6FB)

• ASME B16.20 Performance Test

Kammprofile gaskets are excellently suited for sealing of media under extreme operating conditions, such as high operating pressures and temperatures.

Such solutions are ideal replacements for problem applications associated with other similar gaskets such as:

– metal jacketed

– solid metal

– solid graphite

– or PTFE gaskets.

Kammprofile gaskets are also prefable due to core material can be re-used.

The Salmarcon Kammprofile is a composite gasket which utilizes a serrated metal core with a soft facing material. The metal core is a machined on each contact face with concentric serrations which provide high pressure areas, ensuring that the soft coating flows into any imperfections in the flange even at relatively low bolt loads.

The soft facing material is engineered to compress into the serrations on the core and form a thin film across the peaks creating the ideal sealing density in the grooves of the profile. The result is a gasket which combines the benefits of soft cut materials with the advantages of seal integrity associated with metallic gaskets.

Basis

Graphite, Mica, PTFE or Klingersil C4430 layers with steel cores (SS316-SS304-Duplex-Titanium etc.) as per request or project requirements.

Areas of application

» Petro- Chemical Industry

» Steam applications

» Pipeline systems

» Pressure vessels

» Heat exchangers and coolers

The most basic type of semi-metallic gaskets combining the high pressure suitability and blow out resistance of metallic materials with the improved compressibility of soft materials.

Metal jacketed gaskets offer an economical seal where sealing faces are narrow and can be produced in a variety of shapes, making them a good option for heat exchanger jointing.

General Properties:

›› Economical

›› Easy to handle and install

›› Suitable for high temperatures

›› Suitable for narrow flanges

›› Good blow-out resistance

Applications:

›› Heat exchangers

›› Exhaust gases

›› Valve bonnet gaskets

›› Narrow flanges

Basis

Metallic outer shell with either a metallic or non-metallic compressed fibre filler.

Areas of application

» Oil and Gas industry

» Heat exchanger applications

» General industry » Automotive industry

Key features

» Ideal for assemblies that require a thin-flanged gasket

» Well-suited for the sealing of heat exchangers

» Higher-quality surface sealing of gaskets compared to non-metallic gaskets

Benefits

» Easy handling, solid construction and easy installation

» Ideal for medium- and high-pressure applications

» Excellent chemical resistance

» Suitable for extreme temperature and pressure

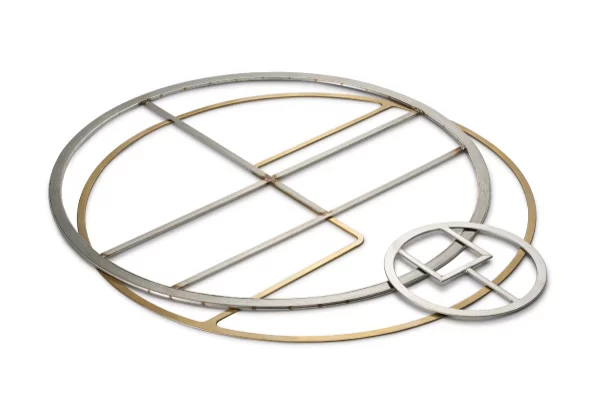

Corrugated gaskets are universally applicable sealing elements.

Due to the wide range of shapes that they can be produced in – including rings, ovals, elongated ovals or frames, with or without dividers, holes and retaining plates -they continue to be used in new areas. The gaskets can be fully or partially coated. Corrugated gaskets with torque support have proven excellent when used with inflexible flanges.

Corrugated gaskets advantages:

›› Outstanding mechanical strength and thermal conductivity

›› Capable of withstanding high temperatures

›› There are almost no limitations regarding size

›› Solid construction provides stability even for large diameters and ensures trouble-free handling and installation.

Even with unmachined flanges, a satisfactory seal can be achieved with the use of suitable soft-material layers. The gaskets can be produced in all the usual sizes up to 6000 mm.

Basis

Stainless steel with a Graphite foil.

Areas of application

» Petro- Chemical industry

» Steam applications

» Oil and gas industry

» Pressure vessels

» Heat exchanger applications

Key features

» Can be produced in – including rings, ovals, elongated ovals or frames

» Can be produced with or without dividers, holes and retaining plates

» Can be produced in all the usual sizes up to 6000 mm

Benefits

» Ideal for older plants and equipment

» Improved resistance to radial shear and thermal cycling

» Effective at low seating stress levels

» Better sealability compared to traditional gasket design

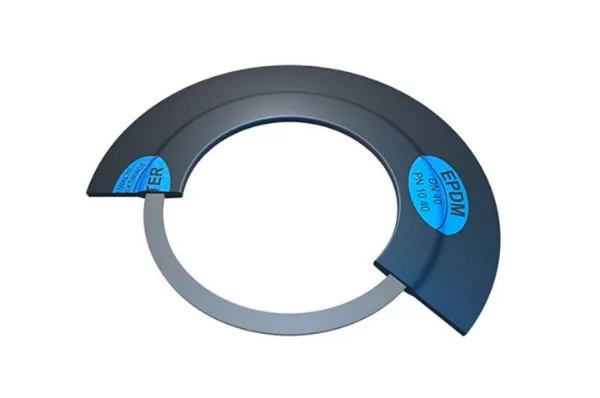

Rubber-steel gaskets have amassed a wide range of applications in sealing technology. Wherever the secure sealing of media with an exceptionally low leak rate, as well as low bolt loads at relatively low temperatures is required, rubber-steel gaskets provide the optimal solution.

Rubber steel gaskets advantages and properties:

›› Self-centering with the same flange DN and PN

›› Appropriate tightening torques

›› Self-limiting compression surface

›› Rigid gasket, easy to install

›› Soft surface in order to seal slightly damaged flange surfaces

›› Materials of KLINGER®KGS: NR, NBR, EPDM, CSM, FKM

›› Dimensions according to EN 1514-1 depending on DN: PN 6 to PN 40 / DN 15 up to DN 2000

Rubber-metal-gaskets are used where safe sealing of conventional up to special industrial media such as gases and liquids are required under usual installation conditions like temperatures, pressures, and forces.

KLINGER KGS rubber-steel seals, the unique and patented adjustable seal KLINGER KGS VD and our KLINGER wall collar offer reliable sealing in water supply and disposal, in plant construction, in gas supply and in building protection.

Basis

Vulcanized rubber mixture, lens-form, rounded at the edges, vulcanized steel ring inside.

Areas of application

» Gas and water supply

» Chemical industry

» Waste water systems

» Vacuum operated pipelines constructions

Key features

» Good reception of the surface load

» Outer diameter self-centering at the inner bolt circle

» Excellent at high flange and screw forces, can easily be absorbed

Benefits

» Excellent in gasket blow-out prevention

» Exceptionally low leak rate

»Low bolt loads at relatively low temperatures

» Seals securely even in uneven locations

With our own technology, knowledge and experience at Salmarcon we are capable of meeting various customer needs.

In close co-operation with customers, we develop and produce special types of gaskets for various applications. Gaskets are produced up to a size 700mm in different types for the most demanding applications in almost any industry.

Custom gaskets are made to customer’s owb drawing and specification, samples and templates. We can provide solution for almost any customer requirements.

Basis

All material types to fit the most demanding applications in almost any industry.

Areas of application

» Petro- Chemical industry

» Powerplants

» Ship building

» Steam applications

» Heat exchangers and coolers

» Valves, Flanges and many more

Key features

» Custom made gaskets according to customers specifications

» Special large single piece gaskets up to 4000 mm in size

» High temperature resistance with plenty materials to choose from

» Capability to compensate for irregularities on flanges

» Our skilled team can provide the solution for almost any customer requirements

Benefits

» Semi-Automatic Semi-metal production line

» Powder painting and polishing line

» Welding line

» Laser marking and quality control extension

» Cammprofiles and Metal jacket production set