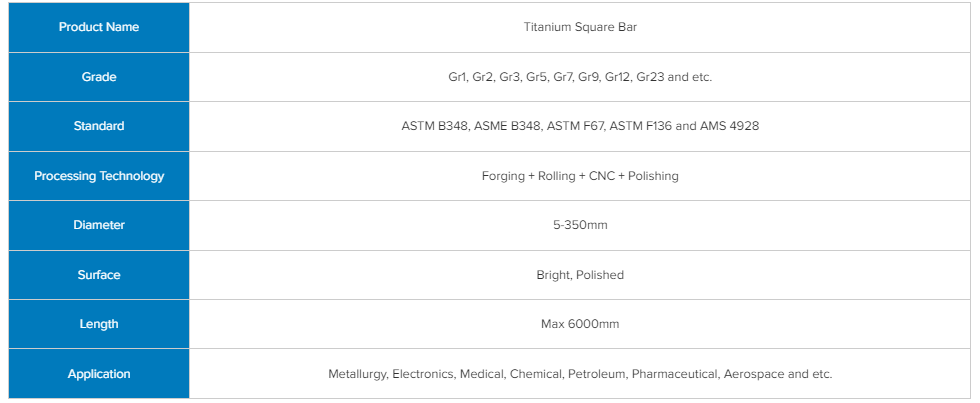

Grade: Gr1, Gr2, Gr3, Gr5, Gr7, Gr9, Gr12, Gr23 and etc.

Surface: Bright, Polished

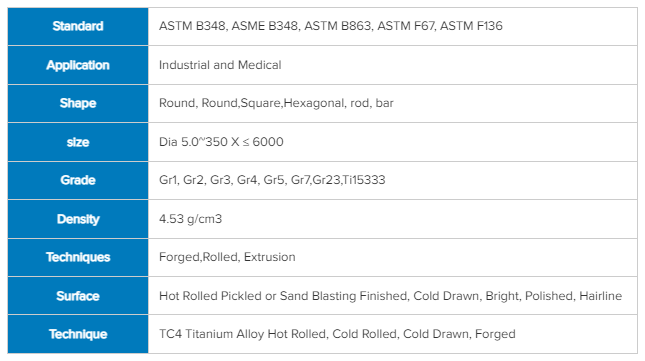

Standard: ASTM B348, ASME B348, ASTM F67, ASTM F136 and AMS 4928

Processing Technology: Forging + Rolling + CNC+ Polishing

DESCRIPTION

The Titanium square bar, also referred to as a rectangular bar, is crafted from titanium and titanium alloys, known for their low density (4.51), lightweight nature, and excellent thermal stability. Widely employed in electroplating and acid metal industries, these square rods find applications in crafting items like hangers and pendants. Standard specifications for titanium square rods encompass dimensions such as 66mm, 88mm, 1010mm, 1212mm, and 14*14mm.

Features of Titanium Square Rod

- Titanium demonstrates robust resistance to corrosion, including acids, alkalis, seawater, and sewage environments.

- Between temperatures ranging from -253°C to 600°C, titanium boasts one of the highest tensile strengths among all metals.

- Titanium is non-magnetic and has a low coefficient of linear expansion.

- Titanium products are known for their low density and high specific strength as well as excellent corrosion and heat resistance. The latest titanium alloy rods are designed for long-term use at temperatures in excess of 600 degrees Celsius, while also being cryogenically resistant.

UT detection standard including:AA, A1,A, B.

Tolerance: h5 – h12

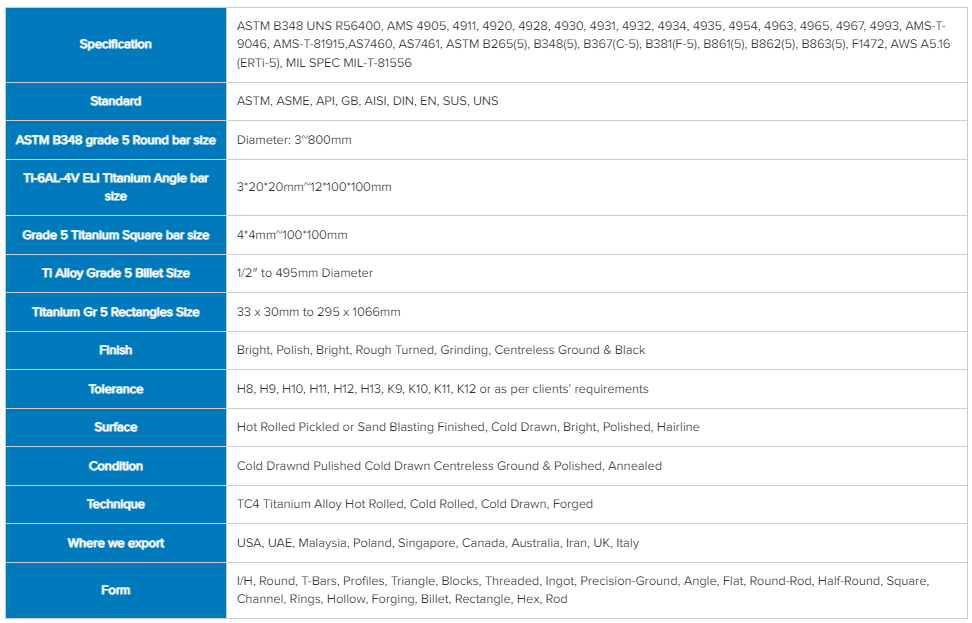

Grade: GR.1, GR.2, GR.3, GR.4, GR.5, GR.7, GR.12, GR.23, Ti-6AL

-4V,Ti-811, Ti-15333, Ti-6242, Ti-662, Ti-1023, Ti6246.

Specification:ASTM, ASME, AMS, ISO, MIL, DIN.

DESCRIPTION

Titanium hexagonal bar is a form of titanium bar.Titanium hexagonal bar is available in a range of sizes and grades including ASTM B348 equivalent of Gr1, Gr2, Gr3, Gr4, or JIS titanium 1, 2, 3, 4, as well as other Ti grades. They are widely used in the Aerospace, Industrial and Medical markets.

Titanium hexagonal bar application

The most common applications for Titanium Bar include aerospace and aviation; petrochemical, gas & oil, the construction of water treatment plants,power generation facilities,and marine vehicles. Titanium’s light weight and extreme durability make it ideal for situations in which strength is required without adding to the overall mass of the finished product.

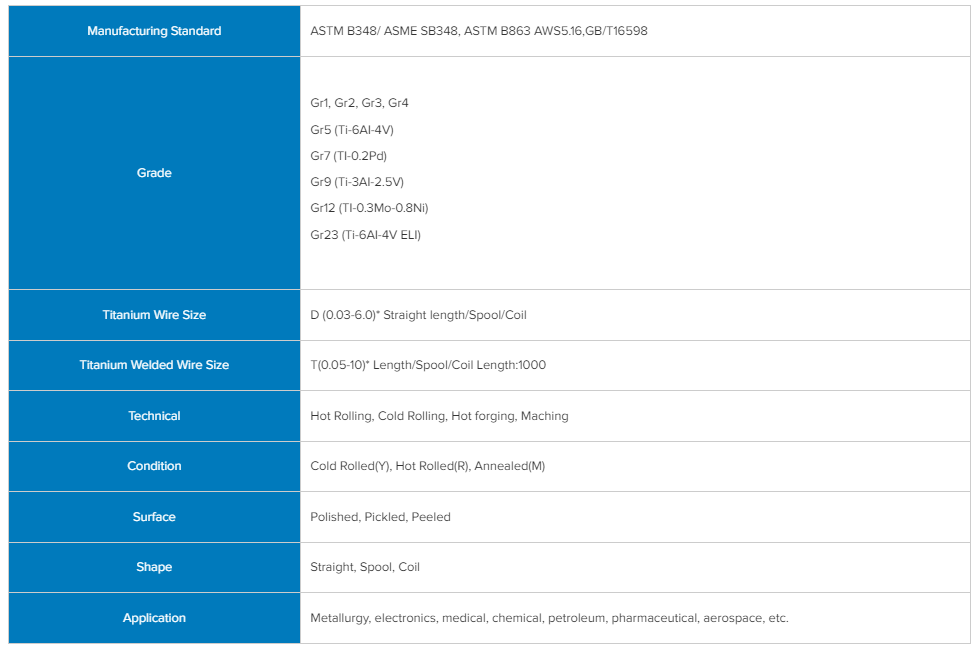

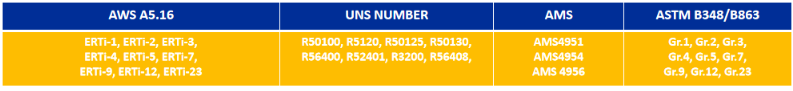

Manufacturing Standard:ASTM B348/ ASME SB348, ASTM B863 AWS5.16,GB/T16598

Grade:Gr1, Gr2, Gr3, Gr4,Gr5 (Ti-6AI-4V),Gr7 (TI-0.2Pd),Gr9 (Ti-3AI-2.5V),Gr12 (TI-0.3Mo-0.8Ni),Gr23 (Ti-6AI-4V ELI)

Titanium Wire Size:D (0.03-6.0)* Straight length/Spool/Coil

Titanium Welded Wire Size:T(0.05-10)* Length/Spool/Coil Length:1000

Technical:Hot Rolling, Cold Rolling, Hot forging, Maching

DESCRIPTION

Titanium wire is a versatile and widely used form of titanium metal in industries such as automotive, aerospace, consumer goods, and defense. It can be produced in various forms and lengths to meet specific application requirements. Titanium wire is known for its strength, corrosion resistance, and high heat tolerance, making it ideal for use in tig welding equipment and hanging applications in the chemical processing industry.

Types of Titanium Wire

Depending on the various characteristics of titanium and titanium alloys, titanium wire can be produced to adhere to a wide range of standards. However, it is typically classified as pure titanium wire, titanium alloy wire, pure titanium eyeglass wire, titanium straight wire, titanium welding wire, medical titanium wire, titanium coil wire, titanium hanging wire, titanium bright wire, and titanium nickel alloy wire.

Pure Titanium Eyeglass Wire

For eyeglass frames, titanium is a robust, lightweight metal that works well. In addition, titanium eyeglass wire’s appealing silver tone and corrosion resistance make it a desirable material. By alloying titanium with nickel, it can also be turned into a memory metal that can bend and return to its original shape, making it the ideal material for eyeglass frames.

Titanium Coil Wire

Specially shaped wires called titanium coils are wound around a core like a wrapped helix. They are renowned for their high melting and boiling temperatures and are remarkably resilient (given their low density). Although titanium coils can be used in various settings, electrical devices are one of their most frequent applications.

Titanium Coil

Welded Titanium Wire

Welded wire made of titanium is the perfect product for demanding industrial applications. It is the ideal material for use in welding and fabrication.

Benefits of Titanium Wire

Titanium wire has high durability and strength. Titanium has the highest strength-to-density ratio, making it more suitable for applications like eyeglass frame manufacturing. Titanium has a neutral resistive property to corrosion. Titanium is extremely recyclable, which lowers production costs. Because of its exceptional ductility, elasticity, and low shear strength at high temperatures, titanium wire is strong.

On the other hand, pushing titanium with your hands does not cause the metal to bend. Due to this characteristic, the wire is ideally suited for structural applications. In addition, the wire is perfect for welding because it can be easily machined, polished, and has a surface with a low coefficient of friction.

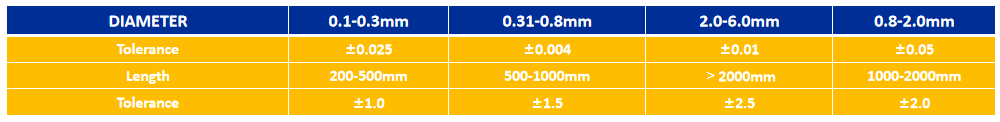

Titanium Wires and Rods:

Size: Dia 1.0-260mm

Type: Titanium straight wires

Specification: AMS 4954, ASTM F136, AMS 4956, ASTM B863, AMS 4951.

We supply 3D Printing Titanium lower oxygen titanium wires and bars for spherical powder.

Titanium Wires Dimension Tolerance:

Titanium Welding Wire:

Size: Dia 0.8-6.35mm

Length: 1000mm & 914mm.

Titanium wires in coil. Titanium wires in spool. D600, D300, D100 spool.

Titanium Wires AWS Classification:

Applications of Titanium Wire

It is used frequently in aerospace and biomedical engineering.

Titanium wire is used for creating parts such as those found in vehicles, boats, and bridges.

Currently, titanium and titanium alloy wires make up more than 80% of all welding wires used in processes, including welding pipes, welding turbine disks and blades for aircraft jet engines, and welding casings.

Titanium wire has been widely utilized in chemical, pharmaceutical, papermaking, and other sectors because of its exceptional corrosion resistance. In addition, it can be turned into a mesh for a chemical drug filter, a seawater filter, or a purified water filter.

Titanium and titanium alloy wires are also used to make fasteners, load-bearing parts, and springs.

Because titanium and titanium alloy wires work well with the body, they are used to make medical devices like pacemakers, defibrillators and battery components.

The manufacture of satellite antennas, clothing shoulder pads, women’s bras, and eyeglass frames utilize titanium alloy wires with shape-memory properties.

Wires made of titanium and titanium alloys are used to create a variety of electrodes in the electroplating and water treatment sectors.

UT detection standard including: AA, A1,A, B.

Tolerance: h5 – h12

Grade: GR.1, GR.2, GR.3, GR.4, GR.5, GR.7, GR.12, GR.23, Ti-6AL

-4V,Ti-811, Ti-15333, Ti-6242, Ti-662, Ti-1023, Ti6246.

Specification:ASTM, ASME, AMS, ISO, MIL, DIN.

DESCRIPTION

Titanium flat bar is a form of titanium bar.Two types of Titanium flat bars are available: pure Titanium flat bar and Titanium alloy flat bar such as Ti-6Al-4V.Titanium flat bars are widely used in aircraft engines and parts, chemical equipment parts (reactors, pipes, heat exchangers and valves, etc),ship hulls, bridges, medical implants, artificial bones, sporting products and consumer goods.

Product Parameter

Titanium Flat Bar Application

Electroplating industry and metal pickling treatment of pendant and pendant production.

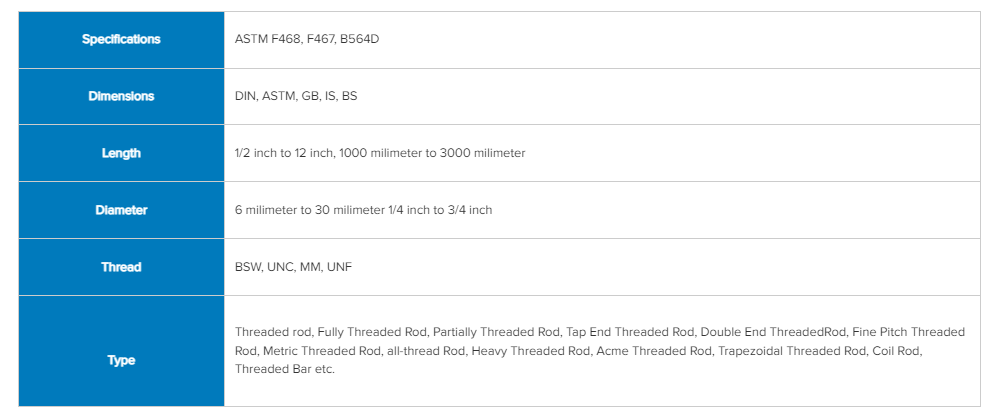

Grade:Gr5&Gr2&Gr8

Material: titanium and titanium alloy

Ti Content (%): 99.6%

Shape: Round

Color: Titanium Original Color

Standard: ASTM B348/ASTM F136

Size: M2.5 to M16

DESCRIPTION

Titanium Threaded Rods are unique compared to other types of threaded rod. This is due to its high strength and corrosion resistance, but lightweight form. Titanium Threaded Rods have the highest strength-to-weight ratio contrasted to other metal rods, with Titanium Grade 5 being four times stronger than 316 Stainless Steel, but with half the weight.Fully resistant to chlorine dioxide, chlorides, hypochlorites and more, they are often found in the pulp and paper industry due to their use of chlorine.

Product Parameter

Features and Applications of Titanium Threaded Bar

Features: low density, high strength, corrosive resistance, acid and alkali resistance, thermal resistance, rustless, no magnetic, fatigue resistance.

Application: Titanium Threaded Bar is widely used in the field of traffic tool manufacturing industry and large machine manufacturing industry, chemical industry,etc.