Titanium bar is made from pure titanium or alloys combining other metals such as aluminum or vanadium. When alloyed, the metal is much stronger. Titanium bar has low density, lightweight, non-magnetic, high strength, excellent corrosion resistance, excellent mechanical properties, and welding performance, widely used in aerospace, medical, automotive, chemical, marine, oil and gas, and other fields. Titanium metal is a metal with a relatively low rejection of the human body. Therefore, the processed parts of medical titanium rods are widely used in human implants and medical devices.

Ti Tube Standards: ASTM B338, B861, B862, DIN 17 861, AMS 4941, AMS 4942

Tube Type: Welded Tube/Seamless Tube

Grade Material: CP Grades 1 – 4, Alloys: Grade 5, 7, 9, 12, 24, 26, 29

DESCRIPTION

Titanium Pipes are made up of different grades of titanium alloys. There are commercially pure grades of titanium and alloyed grades. Titanium Tubes and Pipes are available as Welded and Seamless form and in conformance with leading international standards including DIN, JISC, AMS, GB and ASTM (B338 B861 B862).Titanium is naturally strong and corrosion resistant. The titanium oxide which forms on the surface avoids further oxidation. There are seamless, welded, ERW and fabricated pipes and tubes.

Titanium Seamless Pipes Do Not Have Any Welded Joints Or Parts. These Are Directly Extruded Or Drawn From A Billet And Are Used In Industries Like Hydrocarbon Industries & Refineries, Oil & Gas Exploration & Drilling, And Hydraulic Cylinders, Bearings, Boilers, Automobiles, Etc.

The Titanium Seamless Tube is much smoother and has less absolute roughness. The seamless pipes can be used in precise applications such as equipment and instrumentation. The pipes come under different dimensions based on ASTM, ASME and API standards. Out of all the grades of titanium, the grade 5 is the most used. The Grade 2 Titanium Tubing is a commercially pure grade. The pipes range in nominal bore sizes from ½ inches to 24 inches generally. They also vary in pressure ratings and schedules. The schedules range from 10s to XXS.

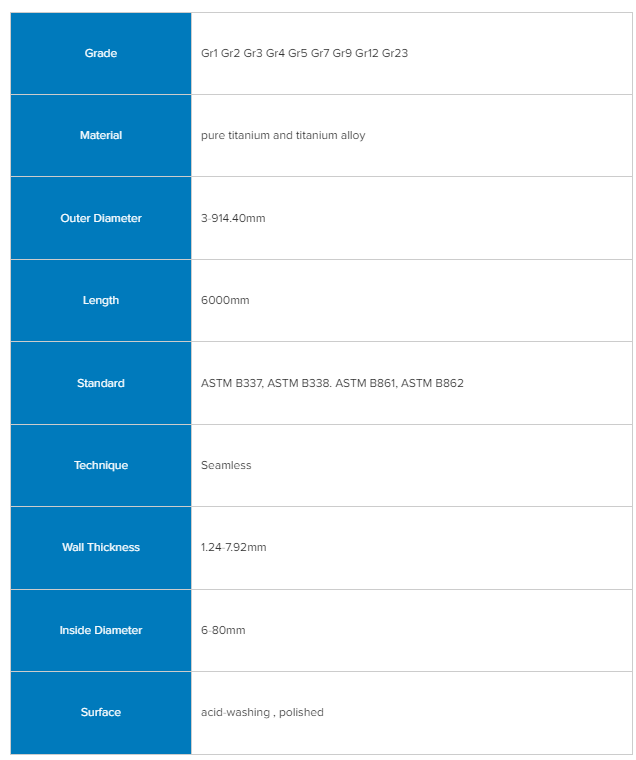

Product Parameter

Titanium Seamless Tube/Pipe Applications:

Titanium tube and titanium alloy tube is used in a wide range of applications including:

Hydraulic systems

Medical implants

Offshore dring

Subsea equipment

Chemical processing plants

Shipbuilding

Power machine building

Condensers

Heat exchangers

Nuclear power

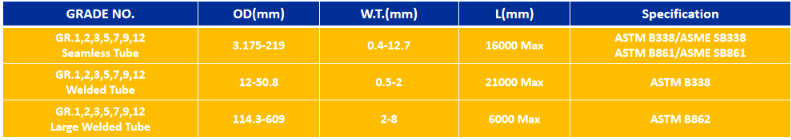

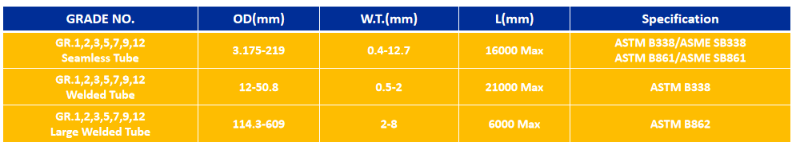

Specification:ASTM B338/ASME S8338ASTM B861/ASME SB861ASTM B338ASTM B862

GRADE NO.:GR.1,2,3,5,7,9,12Seamless TubeGR.1,2,3,5,7,9,12Welded TubeGR.1.2.3.5.7.9.12 W-IT

OD(mm):3.175-21912-50.8114.3-609

L(mm):16000 Mаx21000 Max6000 Max

DESCRIPTION

Titanium and titanium alloy straight seam welded pipe (referred to as “titanium welded pipe”) is welded by coiling and rolling titanium and titanium alloy coils or wide sheets into tube shapes. The titanium alloy grades in the United States mainly include Gr.1, Gr.2 and Gr.12, etc., and the domestic titanium alloy grades mainly include TA1, TA2 and TA10.

Titanium Welded Pipe/Tube production technology is simple, high production efficiency, varieties and specifications, the equipment investment is less, but the general strength is lower than seamless Titanium Pipe, the titanium tube can be widely used for chemical industry and seawater desalination application etc.

Product Parameter

Titanium Welded Pipe/Tube process:

Titanium Welded Tube/Pipe: Titanium Sponge→Compacting Electrodes→Melting →Forging→ Slab→ Hot Rolling→ Cold Rolling→ Ti Strip →Welding →Welded Tube

Application of Titanium Welded Pipe/Tube:

Titanium tubes and pipes ares used in a range of applications including use in industrial pipework, titanium heat exchangers, condensers and evaporators, consumer products, and in medical applications such as implants.

used in the nuclear power industry as unit-standard pipes

automotive parts

chemical and petrochemical industry

wheelchairs

They are frequently used in heat exchange devices such as condensers, evaporators, serpentine heat exchangers, coil heat exchangers, and transmission pipelines.

medical industry

marine industry

hydraulic lines

pulp and paper industry

sporting goods: tennis rackets, golf shafts, bicycle frames, lacrosse equipment

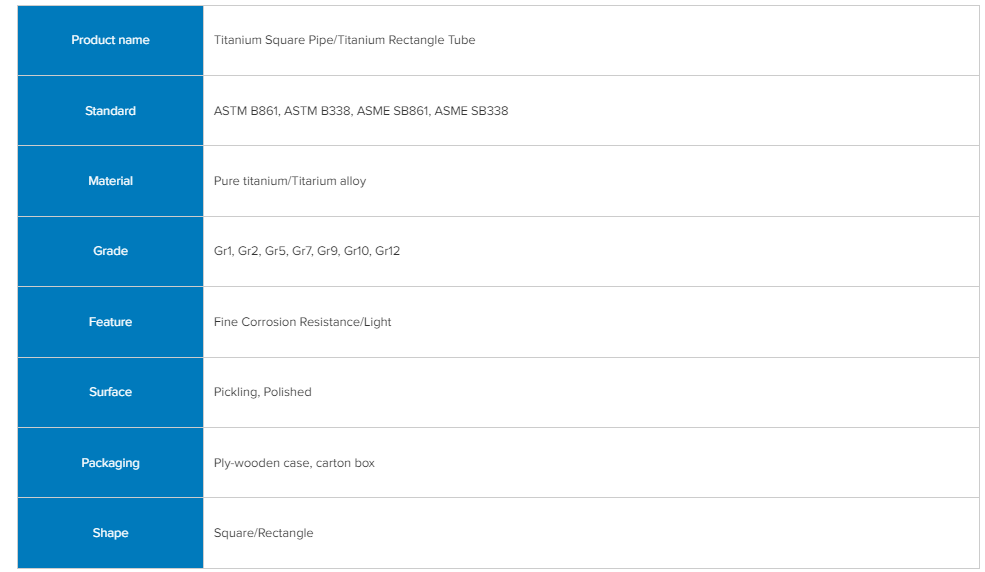

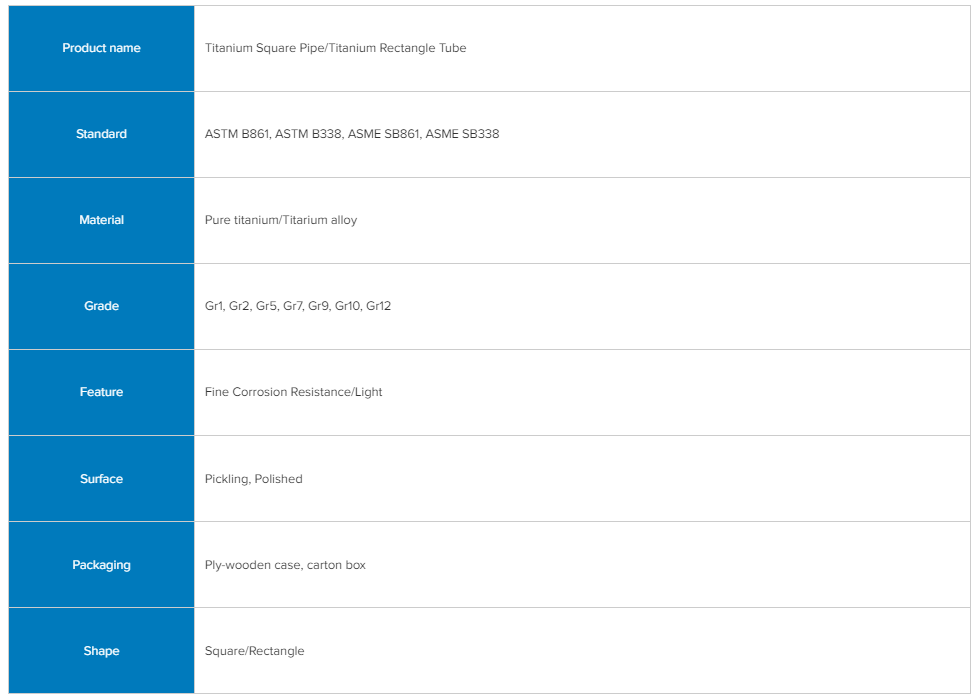

Standard: ASTM B861, ASTM B338, ASME SB861, ASME SB338

Material: Pure titanium/Titarium alloy

Grade: Gr1, Gr2, Gr5, Gr7, Gr9, Gr10, Gr12

Feature: Fine Corrosion Resistance/Light

DESCRIPTION

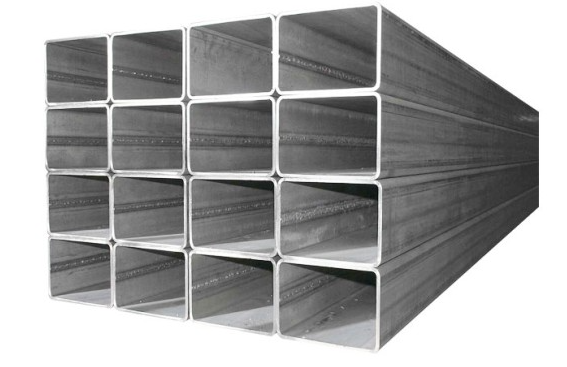

Titanium square tube is a name for square tubes and rectangular tubes, that is, titanium tubes with equal and unequal side lengths. It is made of titanium strip after process treatment. Generally, the titanium strip is unpacked, flattened, crimped, welded to form a round tube, and then rolled into a square tube from the round tube and then cut to the required length.

Titanium square tube can be made as seam square tubes and seamless square tubes.Titanium square pipe has the advantages of a lightweight, high strength, large bending section modulus, metal saving, and easy installation.Moreover, titanium has good corrosion resistance and is not affected by the atmosphere and seawater. So titanium rectangular tubes and titanium square pipes are widely used in various industries.

Product Parameter

The Manufacturing

Seamless tubes are made from hollow billets by a cold drawing process to obtain a product that meets the specified requirements.

Welded tubes are manufactured from flat-rolled products by an automatic arc welding process. The welded pipe shall be sufficiently cold worked to the final dimensions to transform the microstructure of the cast weld into the typical isometric microstructure in the weld during the subsequent heat treatment.

Seamless Titanium Tube process :

Titanium sponge—Compacting electrodes—melting—Forge—Bar billets—Extruding—Rolled—Straightening—Seamless tube

Welded titanium tube process:

Titanium sponge—Compacting electrodes—melting—Forge—Plate billets—Hot rolled—Cold rolled—Titanium scrap—Welded—Welded tube

Titanium square pipe Application:

Titanium square pipe is widely used in chemical industry field, medical field, electronics manufacture, mechanical parts field, automobile industry, and aerospace field, etc.

Bicycle and automobile exhaust pipes, cooling pipes, plating equipment, precision instruments, rings, and environmental protection equipment.

Thermal power engineering: condensers, heat exchangers, engine blades

Vessels: running pipes, submersibles, gas cylinders

Marine engineering: evaporator, heat exchanger, exchanger, oil recovery platform, oil cooler

Chemical engineering: flat plate heat exchanger, flat plate condenser, cooling tower, chlorination drum

Aerospace: engine, fan plate, gas compressor blade, frame, hatch cover, antenna.

Standard: ASTM B861, ASTM B338, ASME SB861, ASME SB338

Material: Pure titanium/Titarium alloy

Grade: Gr1, Gr2, Gr5, Gr7, Gr9, Gr10, Gr12

Feature: Fine Corrosion Resistance/Light

DESCRIPTION

Titanium square tube is a name for square tubes and rectangular tubes, that is, titanium tubes with equal and unequal side lengths. It is made of titanium strip after process treatment. Generally, the titanium strip is unpacked, flattened, crimped, welded to form a round tube, and then rolled into a square tube from the round tube and then cut to the required length.

Titanium square tube can be made as seam square tubes and seamless square tubes.Titanium square pipe has the advantages of a lightweight, high strength, large bending section modulus, metal saving, and easy installation.Moreover, titanium has good corrosion resistance and is not affected by the atmosphere and seawater. So titanium rectangular tubes and titanium square pipes are widely used in various industries.

The manufacturing

Seamless tubes are made from hollow billets by a cold drawing process to obtain a product that meets the specified requirements.

Welded tubes are manufactured from flat-rolled products by an automatic arc welding process. The welded pipe shall be sufficiently cold worked to the final dimensions to transform the microstructure of the cast weld into the typical isometric microstructure in the weld during the subsequent heat treatment.

Seamless Titanium Tube process :

Titanium sponge—Compacting electrodes—melting—Forge—Bar billets—Extruding—Rolled—Straightening—Seamless tube

Welded Titanium Tube process:

Titanium sponge—Compacting electrodes—melting—Forge—Plate billets—Hot rolled—Cold rolled—Titanium scrap—Welded—Welded tube

Product Parameter

Titanium Square Pipe Application:

Titanium square pipe is widely used in chemical industry field, medical field, electronics manufacture, mechanical parts field, automobile industry, and aerospace field, etc.

Bicycle and automobile exhaust pipes, cooling pipes, plating equipment, precision instruments, rings, and environmental protection equipment.

Thermal power engineering: condensers, heat exchangers, engine blades

Vessels: running pipes, submersibles, gas cylinders

Marine engineering: evaporator, heat exchanger, exchanger, oil recovery platform, oil cooler

Chemical engineering: flat plate heat exchanger, flat plate condenser, cooling tower, chlorination drum

Aerospace: engine, fan plate, gas compressor blade, frame, hatch cover, antenna.

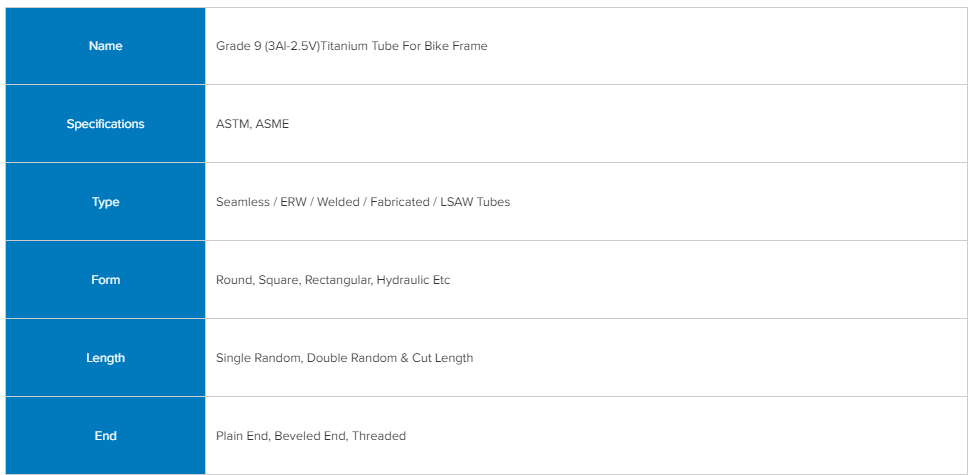

Name: Grade 9 (3Al-2.5V)Titanium Tube For Bike Frame

Specifications: ASTM, ASME

Type: Seamless / ERW / Welded / Fabricated / LSAW Tubes

Form: Round, Square, Rectangular, Hydraulic Etc

Length:Single Random, Double Random & Cut Length

DESCRIPTION

Titanium alloy material has a high tensile, high yield strength, and high pressure bearing capacity. It contains half the density as that of steel, however, it is much stronger than steel. This makes it a popular material for use in the competitive cycling industry.

The unique performance of titanium material makes it an excellent material for making bicycle frame. Its high strength, low density, low elastic modulus, excellent fatigue resistance and corrosion resistance make the Gr9 Titanium Seamless Tubes For Bike Frame made not only very strong and durable but also very light. GR9 titanium alloy material (Ti-3Al-2.5V) is widely used in bicycle frames.

Grade 9(3Al-2.5V) titanium is an alloy consisting of 3% aluminum, 2.5% vanadium, and 94.5% pure titanium. The properties critical to bicycle tubing are best served by a high quality 3-2.5 seamless tube. Excellent fatigue life, property consistency, form-ability, and corrosion resistance of Grade 9(3Al-2.5V) Titanium Tube for bike frame are but a few of the reasons 3-2.5 is still the premier frame material.

Product Parameter

The motorsports, sports equipment and bicycle markets have found grade 9 titanium tube very beneficial to their applications because of the light-weight and strength of titanium. The Titanium Bicycle tubing was used to make both mountain bike and road bike frames with tapered chainstay and seat stay. Up to this point, titanium bicycle tubing was mainly titanium electrical conduit for aircraft applications.

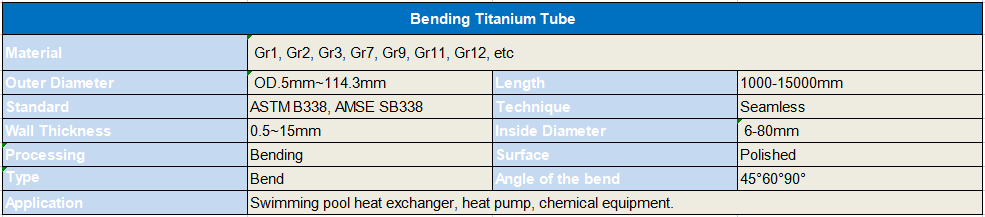

Material:Gr1, Gr2, Gr3, Gr7, Gr9, Gr11, Gr12

Outer Diameter:OD.5mm-114.3mm

Wall Thickness :0.5-15mm

Processing:Bending

Standard:ASTMB338,AMSE SB338

DESCRIPTION

Bending Titanium Tubing refers to the process of shaping and forming titanium tubes, a highly versatile and lightweight metal alloy known for its exceptional strength-to-weight ratio and corrosion resistance.

Originating from the aerospace industry, where titanium’s inherent properties make it ideal for structural components, this technique has expanded into various sectors such as biomedical, chemical processing, and marine applications.

Titanium tubing, typically available in sizes ranging from 1/8 inch to 2 inches in diameter, undergoes precise bending using specialized machinery to create intricate shapes and fittings.

Industry standards like ASTMB338, AMSE SB338 dictate the manufacturing processes and quality control measures. Its widespread applications include fuel lines in aircraft, medical implants, heat exchangers in power plants, and even subsea pipelines.

Product Parameter

Bending Titanium Tube Processing:

Titanium sponge→melt to ingot(control the content of chemical composition according to the Standard and customized)→forging(forged billet)→scalping→tube billet(made by extrusion)→rolling(get semi-finished tube)→annealing( vacuum annealing furnace)→straightening→tailor→pickling(nitric acid solution)→finished tube→testing(dimension and mechanical property)→packing→shipping.

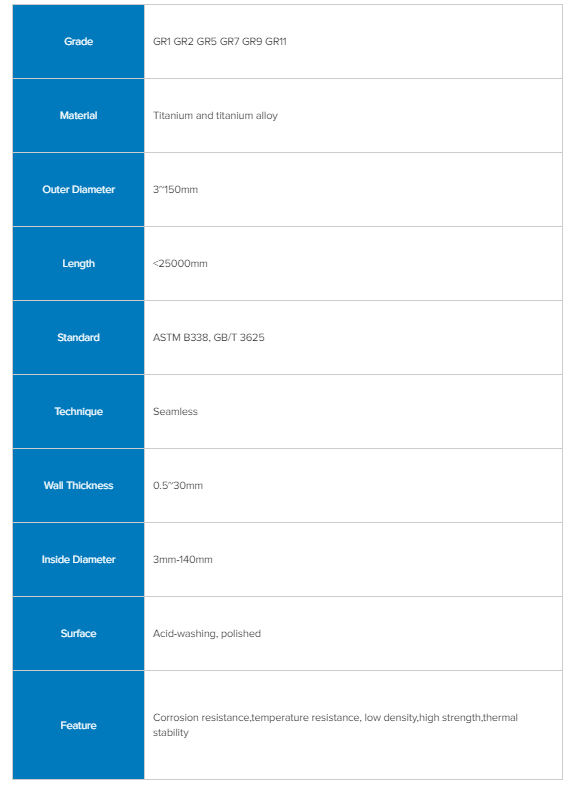

Grade: GR1 GR2 GR5 GR7 GR9 GR11

Material: Titanium and titanium alloy

Outer Diameter:3~150mm

Length: <25000mm

Standard: ASTM B338, GB/T 3625

Technique: Seamless

DESCRIPTION

Titanium has plasticity, the elongation of purity titanium can be up to 50-60%, and the reduction of area can be up to 70-80%. That makes the production of titanium capillary tube. Forging and rolling the secondary melting titanium ingots into the tube billets, then stretch the tube billet for several times until the titanium capillary tube formed. Due to the good compatibility with human body and corrosion resistance, titanium capillary tube is widely used in the medical industry, including the human body implants, medical equipment internal precision parts, etc.

Product Parameter

Application of Titanium Capillary Tube:

- General service industries (petroleum, food, chemical, paper, fertilizer, fabric, aviation and nuclear).

- Fluid, gas and oil transport.

- Pressure and heat transmission.

- Construction and ornament.

- Boiler heat exchangers.

- Motorbycle and bike.

Grade: Gr1 Gr2 Gr3 Gr4 Gr5 Gr7 Gr9 Gr12 Gr23

Material: pure titanium and titanium alloy

Outer Diameter: 3-914.40mm

Length: 6000mm

Standard: ASTM B337, ASTM B338. ASTM B861, ASTM B862

Technique: Seamless

DESCRIPTION

Titanium Coil Tube was bended from Titanium Tube and is used extensively in the use of Heat Exchangers and offers an ideal material due to its weight, strength and corrosion resistance. We manufacturered according to the customized drawing strictly. We also manufacture the coils in special sizes and shapes, like superfine U coils, spiral coil, box type coil, drum type coil, S type coil, tapered, oval type coil, circular coils, serpentine coil, double helical coil, triple helical coil, half pipe coils.

Product Parameter

Feature of Titanium Tube Coils:

Low Density and High Strength

Excellent Corrosion Resistance in acid and alkali salt

High heat transfer capability

Good biocompatibility

Low elasticity module

Low thermal expansion coefficient

Superior strength-to-density ratios

Good strength at low and high temperature

Good resistance to effect of heat and low temperature

High mechanical property

Bright surface

Varity dimension supported

UT, RT test supported

Offer you customized services with most competitive price

Applications of Titanium Tube Coils:

Bicycle and automobile exhaust tubing ,cooling pipe,Electroplating equipment,precision instruments,ring,environmental protection equipment.

Thermal power engineering:condenser, heat exchanger, engine vane.

Vessels:Running pipes, submersible,gas cylinder.

Oceaneering: evaporator, heat transmitter, exchanger,oil production platform, oil cooler.

Chemical engineering:Flat plate heat exchanger, flat plate condenser,cooler tower,chloride barrels.

Aerospace:Engine, fan plate, gas compressor vane, rack, hatch cover, empennage.

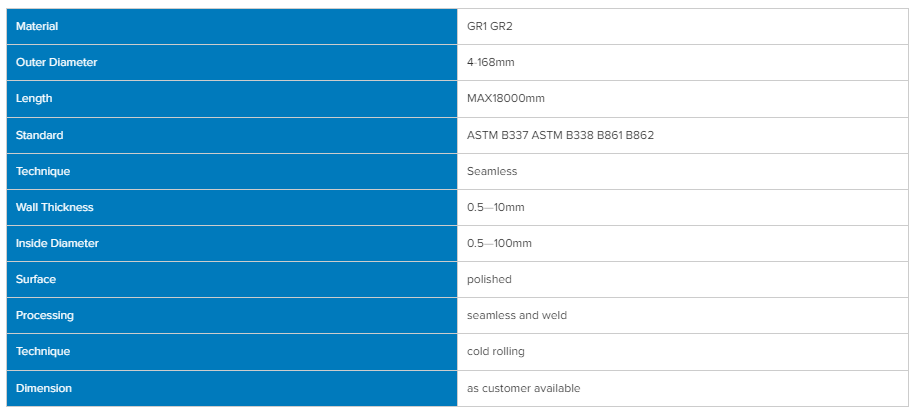

Material: GR1 GR2

Outer Diameter: 4-168mm

Length:MAX18000mm

Standard: ASTM B337 ASTM B338 B861 B862

Technique: Seamless

Wall Thickness: 0.5—10mm

DESCRIPTION

Titanium Heating Coil and Titanium Cooling Coil are made out of titanium pipes or tubes with dia 8mm – 65mm as per ASTM B 337/338, Gr.1 or Gr2, applied to chemical, electroplating and metal finishing industries to heat or cool the chemical bath.

Product Parameter

Features of Titanium Spiral Tube

High heat transfer efficiency

The diameter, wall thickness, and length of the titanium corrugated tube are the same. The thermal efficiency is 1.3-2.6 times that of a straight titanium tube.

Strong corrosion resistance

The heat transfer tube-Gr1 titanium corrugated tube, made according to standard GB/T3625-1995, are 4 times 43 bar high pressure test and precise halogen leaking test in the Production. And 100000 times 4.5 bar fatigue test to make sure no leakage.

Descaling ability

4/6 head titanium corrugated tube is without welds. It can greatly reduce the leakage. It also can be turbulent flowing, which reduce the rate of scale formation. So as to prolong service life, and reduce maintenance costs.

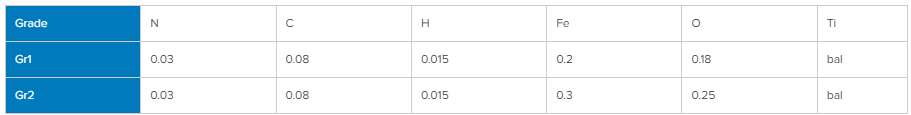

Chemical Composition of Titanium Coil Spiral Tube

Mechanical Properties of Titanium Coil Spiral Tube

Application of Titanium Spiral Tube

Titanium Spiral Tube is widely used for mariculture, seawater heat transfer, saline heat transfer, the chemical industry, the food Industry, Metallurgy, refrigeration, the light industry, the plating industry, aluminum oxidation tank, salt manufacturing, paper making, ultrasonic, telecommunication and central heating etc.

Usage of Titanium Spiral Tube

Water tank, boiler, heat exchanger unit, absorption type refrigerator, turbo refrigerator and screw refrigerators; distillation facility with multiple effects etc.

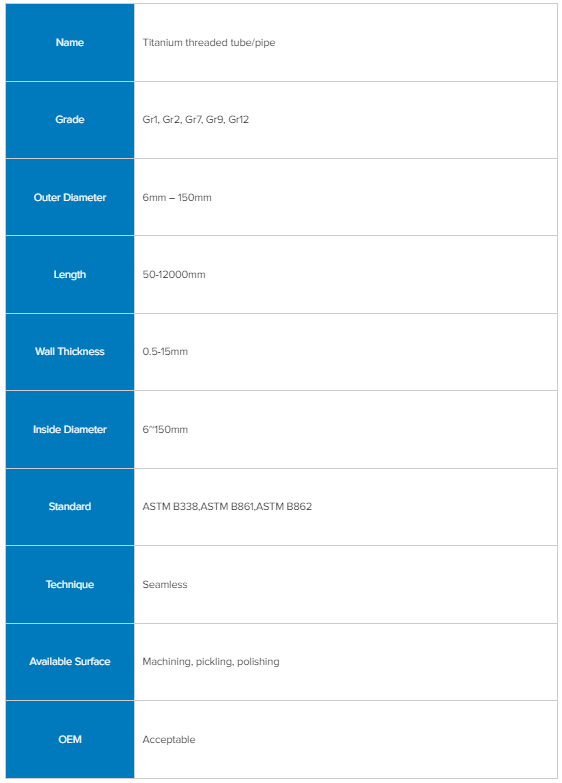

Name: Titanium threaded tube/pipe

Grade: Gr1, Gr2, Gr7, Gr9, Gr12

Outer Diameter: 6mm – 150mm

Length: 50-12000mm

Wall Thickness: 0.5-15mm

Inside Diameter: 6~150mm

DESCRIPTION

The Titanium Threaded Tube is a kind of Titanium Pipe with threads. Professional manufacturing and exporting titanium threaded tube. We can custom manufacturing titanium threaded pipe according to your requirements.

Product Parameter

Titanium Threaded Tube Types

-InsideThreaded Titanium Tube : the out diameter is 35mm, wall thickness 3-3.5 mm, M5. Surface polished.

-Outside Threaded titanium tube: the out diameter is 25.4mm and 19mm, wall thickness 1mm, M3. Surface polished.

Titanium Threaded Tube Applications

The titanium tube is light in weight, high in strength, and superior in mechanical properties. It is widely used in heat exchange equipment, such as tube and tube heat exchangers, coil heat exchangers, serpentine tube heat exchangers, condensers, evaporators, and transportation pipelines. Many nuclear power industries use titanium tubes as standard tubes for their units.

Outer Diameter: 3-100mm

Length: 1000-3000mm

Standard: ASTM 337 338

Technique: Seamless

Grade: Gr1, Gr2, Titanium Alloy

Wall Thickness:0.4~7mm

DESCRIPTION

A titanium heat exchanger is a heat-transfer device, made of titanium or its alloys, that is used for the transfer of internal thermal energy between two or more corrosive fluids. Titanium Heat Exchanger U Tube manufactured to ASTM B338/ ASME SB-338 are widely applied for the fabrication of tubular heat exchangers. Titanium has the super strong corrosion resistant ability. The Titanium heat exchangers use seamless pure titanium tubes as heat conductor, which can be used for a long time thus are cost-saving for after-sale services.

Product Parameter

Titanium U-Tube Advantages:

According to the customer’s application field, different designs can be made into disc shape, round shape, tube, coil or profile.

The whole Titanium Tube is processed, which reduces the direct joint of the tube and is more durable.

According to the environment used, use pipes of different specifications and thickness to meet customer requirements to the greatest extent.

Strong corrosion resistance.

Titanium U-Tube Application Field:

Bicycle and automobile exhaust tubing ,cooling pipe,Electroplating equipment,precision instruments,ring,environmental protection equipment.

Thermal power engineering:condenser, heat exchanger, engine vane.

Vessels:Running pipes, submersible,gas cylinder.

Oceaneering: evaporator, heat transmitter, exchanger,oil production platform, oil cooler.

Chemical engineering:Flat plate heat exchanger, flat plate condenser,cooler tower,chloride barrels.

Aerospace:Engine, fan plate, gas compressor vane, rack, hatch cover, empennage.